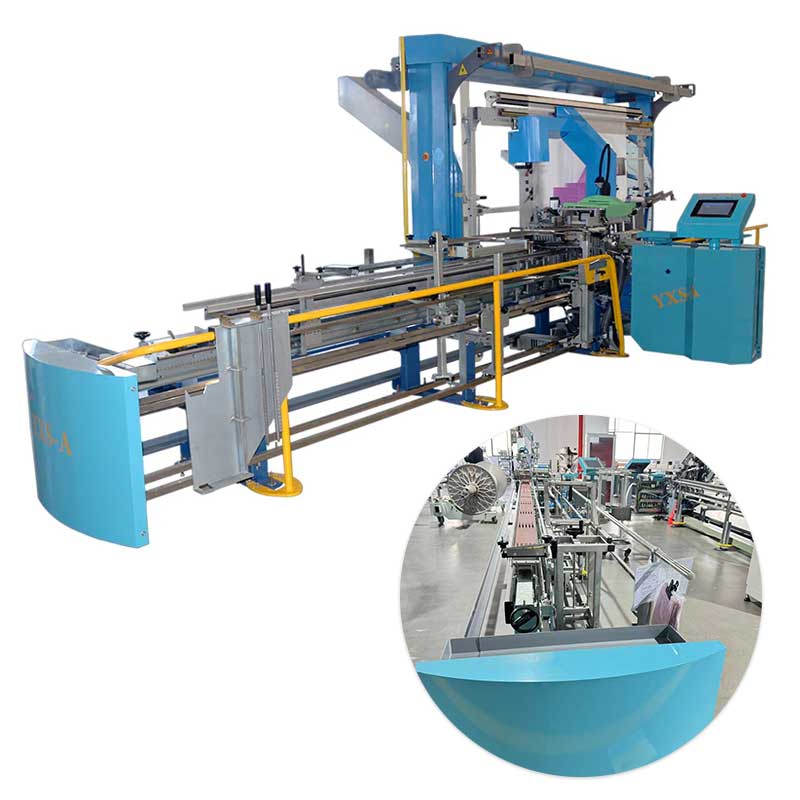

Product recommendation

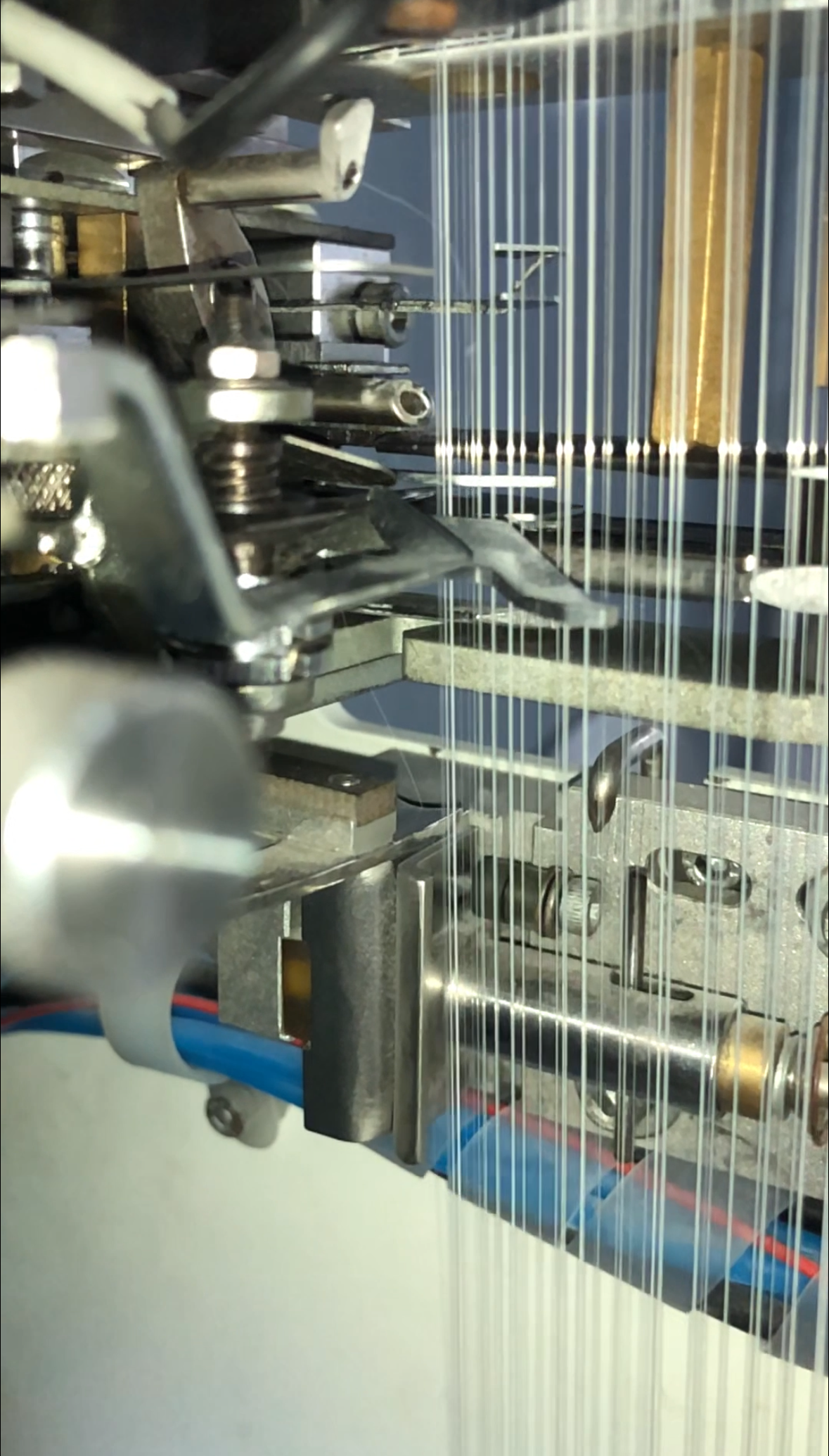

The motor drives the mechanical cam to drive the yarn picking needle to reciprocate and separate the yarn on the yarn driving machine. During the yarn separation process, double yarns will appear due to sizing or yarn accumulation. At this time, the sensor matching the yarn tension detection will send a signal to the control system, the equipment will stop, and the operator will manually click the empty heald button of the equipment to process the empty heald. After the system judges that the tension of a yarn picked by the yarn picking needle is correct, the separation finger separates the current yarn from the yarn layer, and the yarn feeder hooks the yarn to the scissors to cut it. At the same time, the yarn clamping device assembly will keep the current yarn at the separation finger position, waiting for the sword belt hook to hook it and pass it through the dropper, heald, and reed. (The selection of the yarn picking needle model is based on the thickness of the customer's weaving shaft yarn. For example, 60-count yarn needs to match a No. 12 yarn picking needle, and the yarn picking needle is installed on the needle seat.)

Please visit product page for more information

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts