The Value of Nylon Stop Plates in Textile Machinery Continues to Stand Out

2025-12-29

—High Wear Resistance and Low Noise Solutions Facilitate Stable Equipment Operation

As the textile manufacturing industry continues to develop towards higher speeds, continuous operation, and automation, textile machinery places higher demands on the stability, wear resistance, and operating noise of its components. As a key auxiliary component in textile machinery, nylon stop plates are finding increasingly widespread application in looms, spinning machines, and other equipment due to their comprehensive performance advantages.

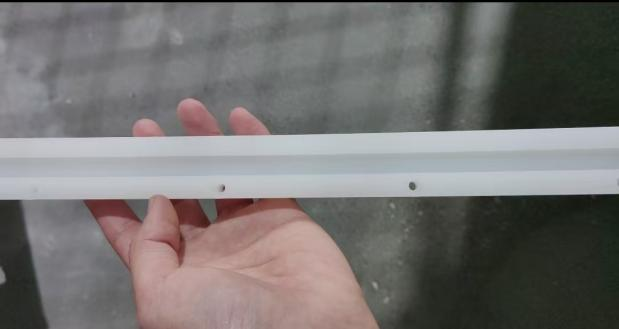

Nylon stop plates are primarily used for limiting the stroke, fixing the position, and providing cushioning protection for moving parts in machinery. Common installation locations include loom guide systems, transmission structures, and the periphery of reciprocating motion components. During high-speed operation, stop plates effectively prevent components from over traveling, impacting, or abnormally wearing, thereby ensuring the safety and stability of the entire machine.

Compared to traditional metal stop components, nylon materials offer significant advantages such as light weight, high wear resistance, good self-lubricating properties, and excellent impact resistance. In practical applications, nylon limit plates not only reduce the coefficient of friction and lubrication dependence, but also effectively absorb vibrations and shocks generated during machinery operation, significantly reducing equipment noise and improving the comfort of the production environment.

Furthermore, high-quality nylon limit plates typically use engineering-grade nylon materials (such as PA6, PA66, or reinforced nylon), maintaining good mechanical strength while possessing stable dimensional accuracy and a long service life, meeting the high-load, long-term continuous operation requirements of textile workshops. Some products can also be customized according to different machine models and application scenarios to meet customers' personalized requirements in terms of size, tolerances, and installation methods.

In the current context of cost reduction and efficiency improvement and refined equipment management in the textile industry, nylon limit plates, with their advantages of reducing maintenance frequency, extending equipment life, and improving operational stability, are gradually becoming an important choice for upgrading textile machinery parts. In the future, with the continuous optimization of material technology and processing technology, the application potential of nylon limit plates in the textile machinery field will be further released.