Product recommendation

The principle of the warp stopper of a loom is to stop the supply of warp yarns to the loom through a device called a "warp stop bar", so as to achieve the effect of warp stop. The warp stop bar is on one side of the loom and is connected to the working mechanism of the loom. When the warp stop bar rises, it will lift a component called a "warp stop comb". The warp yarn is pulled out of the yarn feeder of the loom, thereby stopping the supply of warp yarns. When the warp stop bar drops, the warp stop comb will release the warp yarn, and the loom can continue to work.

The principle of the warp stopper is based on the operation of the loom during operation, stopping the warp yarn on the loom in order to perform certain specific operations, such as changing yarns and adjusting the machine. The use of warp stoppers can effectively reduce the failure rate of looms and improve production efficiency.

Please visit product page for more information

-

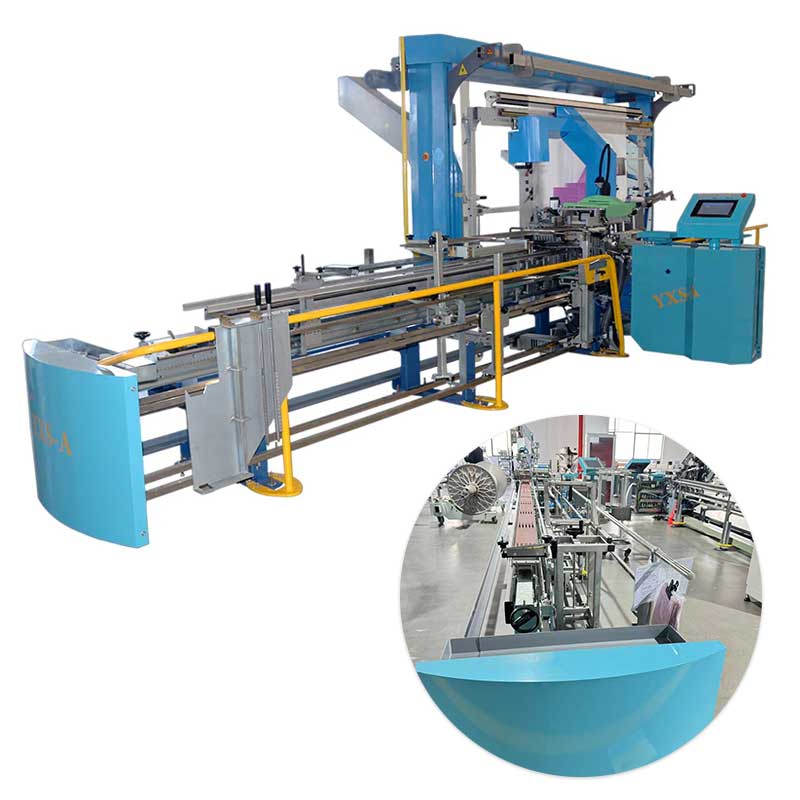

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts