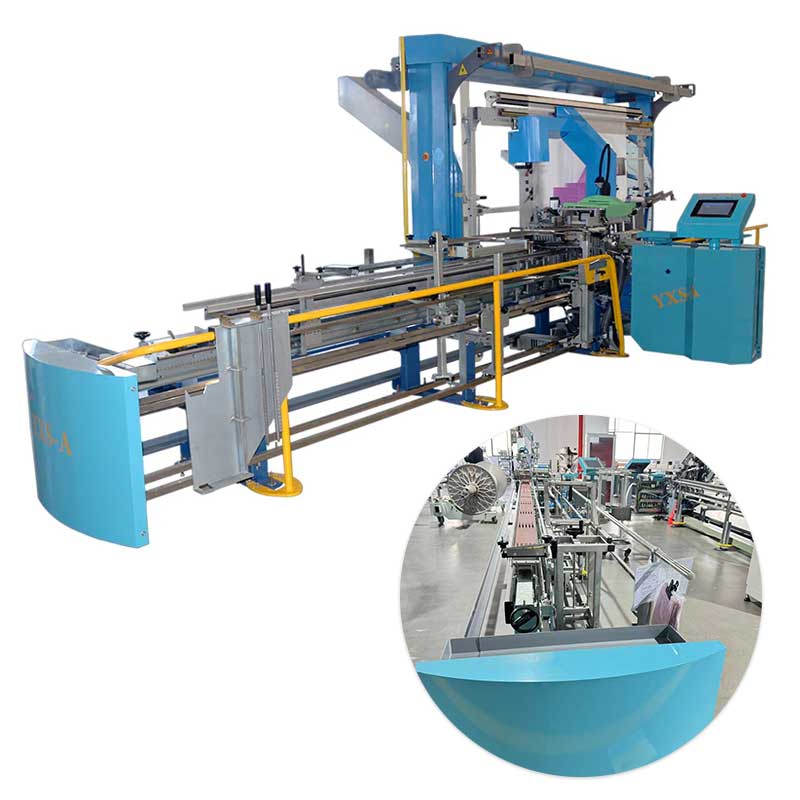

Product recommendation

The warp drawing machine was really introduced and put into use by Chinese textile factories around 2003. Its efficient working ability attracted more and more yarn-dyed fabric manufacturers. Since the cotton short fiber process requires the use of warp droppers, basically all of them introduced Delta110, and the yarn-dyed warp beam must be skeined before drawing into the heald.

At this time, the function of the machine can meet the needs of most heald frame textile factories, such as cotton, wool clothing fabrics and bedding fabrics, especially suitable for yarn-dyed factories and glass fiber base fabric weaving factories. The machine has functions such as double warp self-stop detection and pattern plate cycle stop inspection.

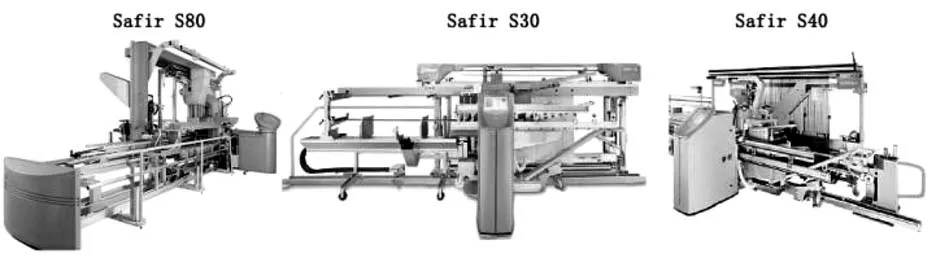

Since 2007, the functions of different use environments have been more comprehensive and refined. The first S80 filled the functional requirements of the two independent yarn sheets of two warp beams that the Delta series did not have at the same time to draw into a weaving process variety, expanding the use scenarios of the warp drawing machine, especially the pre-weaving preparation of towel looms. The fastest warp drawing speed is 160 yarns/min, and the output is 40,000 to 50,000 yarns/8 h.

The S30, which was tried in 2010 and officially launched in 2012, removed the dropper module specifically for chemical fiber weaving, and raised the drawing speed to 200 yarns/min. Later, by optimizing the control software and improving the unit drive, the speed was raised to 230 yarns/min, with an output of 70,000 to 80,000 yarns/8 hours. At the same time, based on the convenience of operation and the process characteristics of chemical fiber weaving, in order to reduce the cost of using the site and subsequent auxiliary equipment, a fixed yarn frame was created as a workstation, and the design of the mobile head rotating in two stations for drawing operations greatly facilitated the use of weaving manufacturers. In 2014, based on this concept, the S40 drawing-in machine was developed for simpler weaving plants that need to simultaneously draw in dropper wires. The S30 is suitable for O-type healds, and the S40 is suitable for C, J, and O-type healds.

Please visit product page for more information

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts