Product recommendation

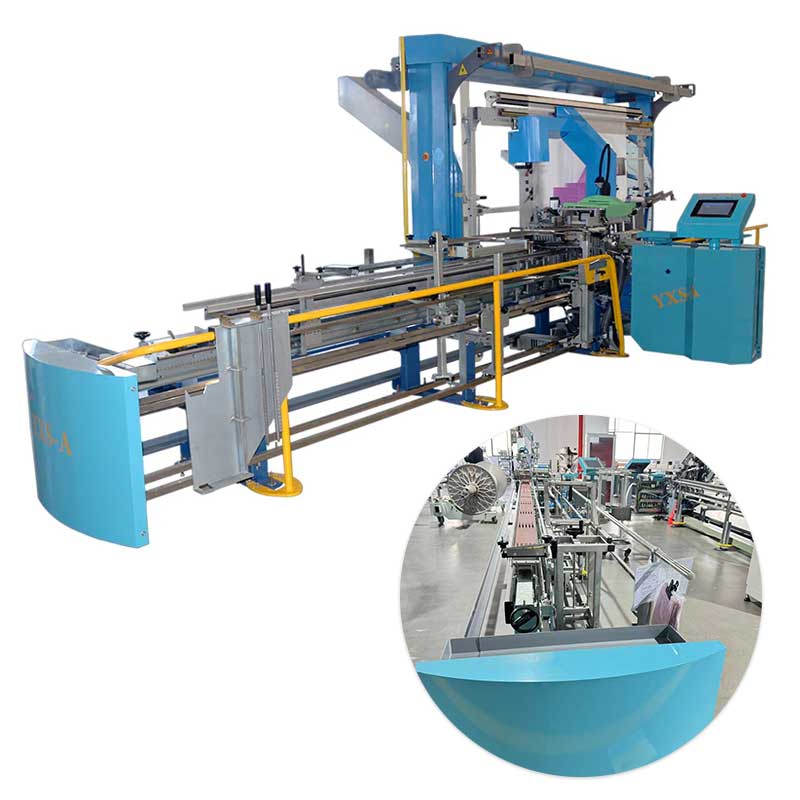

With the advancement of modern technology, the weaving speed has greatly improved, but the warp knitting operation is still mainly manual, which has problems such as slow speed, low efficiency, and long cycle, and cannot meet market demand. The use of automatic warp knitting equipment has become a development trend. In the field of high-end textile machinery equipment, automatic warp knitting machines are known as the "bottleneck" technology in the industry chain. Their production technology has long been monopolized by foreign enterprises, with high prices and extremely complicated after-sales service processes. We are currently promoting a domestically produced automatic warp knitting machine with a small equipment investment and the following performance characteristics:

1. Machine vision technology: Identify the position and width information of the steel reed to achieve precise positioning of the steel reed.

2. Single and double yarn recognition technology: Using tension sensors to detect real-time changes in yarn tension, the control system realizes the recognition of single and double yarns based on the changes in tension.

3. Universal algorithm for warp pattern control: Based on the requirements of weaving technology, research a universal warp pattern control algorithm to meet the warp requirements of different weaving enterprises.

4. The system runs stably and has a high threading speed, which is about 7 times faster than manual threading speed.

5. Use a human-machine interface to monitor the entire system. Implement system parameter input, configuration of warp pattern, fault diagnosis and alarm through human-machine interface. Real time monitoring of the operating status of the system, user-friendly interface, and convenient operation.

6. Adopting bus based servo control technology, the driving system operates more stably and reliably, with strong anti-interference ability

Please visit product page for more information

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts