Product recommendation

When the fabric glides off the loom, it is no longer yarn but a piece of mass-producible silence. Not a single protruding fibre is visible under a standard 600 lux beam; the surface shows a uniform matte—this is the ex-works condition of the latest 2.8 m-wide, 200 ends/cm high-count satin bedding fabric from Jiangsu Mingyuan Home Textiles. The zero-defect outcome was not decided by the final inspection, but by an order written long before the 14 000 parallel ends were still resting on the warp beam: an automatic drawing-in machine threaded every drop wire, heald wire and reed wire in one pass, compressing tolerances to 0.02 mm and embedding the gene of silence into high-speed weaving.

1. The Rehearsal on the Warp Beam

02:30, lights dimmed to 30 %. A Stäubli SAFIR S80 works the night shift unattended. Machine vision identifies colour and twist of every end at 160 ends/min; Active Warp Control 2.0 compares the data in real time, rejecting any yarn whose shade deviates by 0.3 %. Twin-servo motors in the drop-wire module run each stainless plate through a caliper check; any thickness beyond 0.005 mm is discarded on the spot. Before a heald wire is allowed to accept a yarn, an IR beam scans the eye for burrs invisible to the naked eye. In 8 hours the machine composes a four-layer warp score out of 48 000 ends, a symphony that will not miss a single note.

2. Silence in the Weaving Zone

08:00, the beam is rolled onto an OptiMax-i3.0S loom. The clearance between reed wire and heald wire is set to the physical minimum; at 600 rpm the friction between heald wire and drop wire is only 55 dB—quieter than an air-conditioner. Ruyi 420J2 stainless heald wires present a mirror-smooth channel, letting yarn tension fluctuate by merely 0.1 g during high-speed shedding. Ends break 0.3 times per 100 000 picks. The plant no longer crackles with snap alerts; only the steady bass hum of the loom remains—the most audible side effect of the upgrade: noise has vanished.

3. Ciphers at the Finishing Gate

16:00, the grey fabric enters finishing. Because potential yarn damage was virtually eliminated upstream, singeing needs only one pass to reach grade-4 smoothness, saving 30 % natural gas. On the sanforiser the cloth runs at 18 m/min with a skew kept under 0.5 %—no manual stenter is required. When the roll is finally batched, no trace of “lettuce edges” can be found. An RFID tag is auto-applied, encoding the drawing-in batch, heald-wire lifetime and drop-wire thickness—data ciphers for any future flaw trace-back.

4. Echoes in the End Market

Three weeks later the fabric is sewn into luxury hotel bedding and laid in a newly opened suite on Shanghai’s Bund. The guest’s first-night review reads: “Sheets make almost no rustle; no static crackle when turning.” The sentence is scraped by the system and pinged back to Mingyuan’s cloud. An engineer opens the dashboard; the curve for the drawing-in batch, the serial numbers of the heald wires and the thickness profile of the drop wires light up in unison. The silence of a single piece of cloth had already been written into its genes when it was still a field of parallel ends on the warp beam.

Please visit product page for more information

-

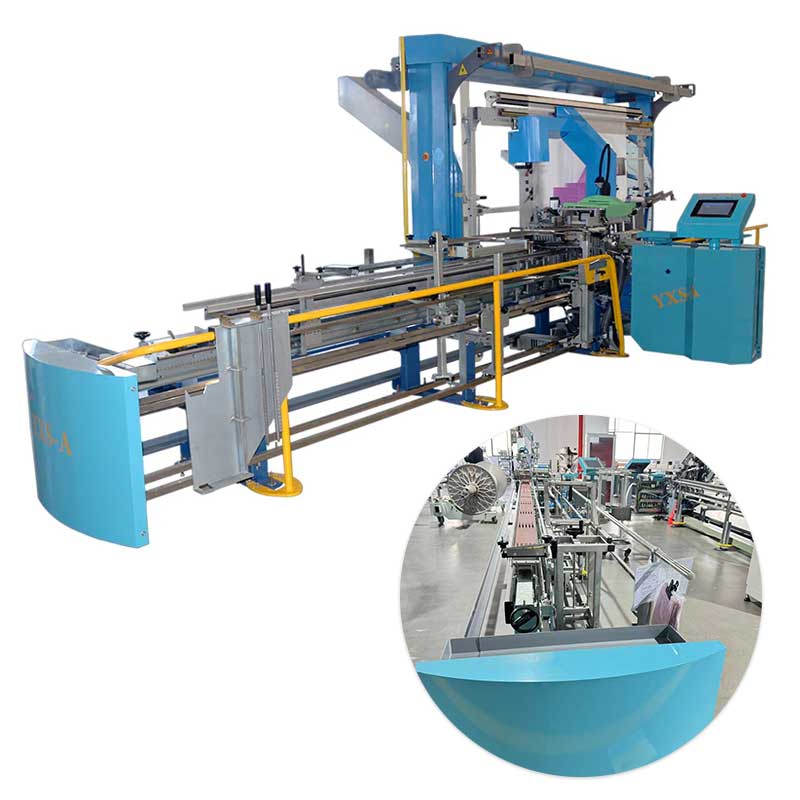

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts