Product recommendation

Driven by the wave of Industry 4.0, China's textile machinery sector has achieved a major technological breakthrough — the new generation of automatic drawing in machine has officially entered industrial application, marking a crucial step in the intelligent transformation of core processes in the textile industry. This innovative equipment, integrating machine vision, artificial intelligence (AI) and precision control, is redefining the efficiency standards and quality systems of textile production.

Breaking Technical Bottlenecks to Achieve Full Automation

The traditional warp threading process is known as a "delicate embroidery-like task" in textile production, relying entirely on skilled workers to complete manually. Operators need to thread thousands of warp threads through drop wires and reeds one by one among dazzling yarns, and the position and tension of each thread must be precisely consistent. A skilled worker can only thread a maximum of 8,000 to 10,000 threads per day, while needing to maintain high concentration, resulting in extremely high labor intensity.

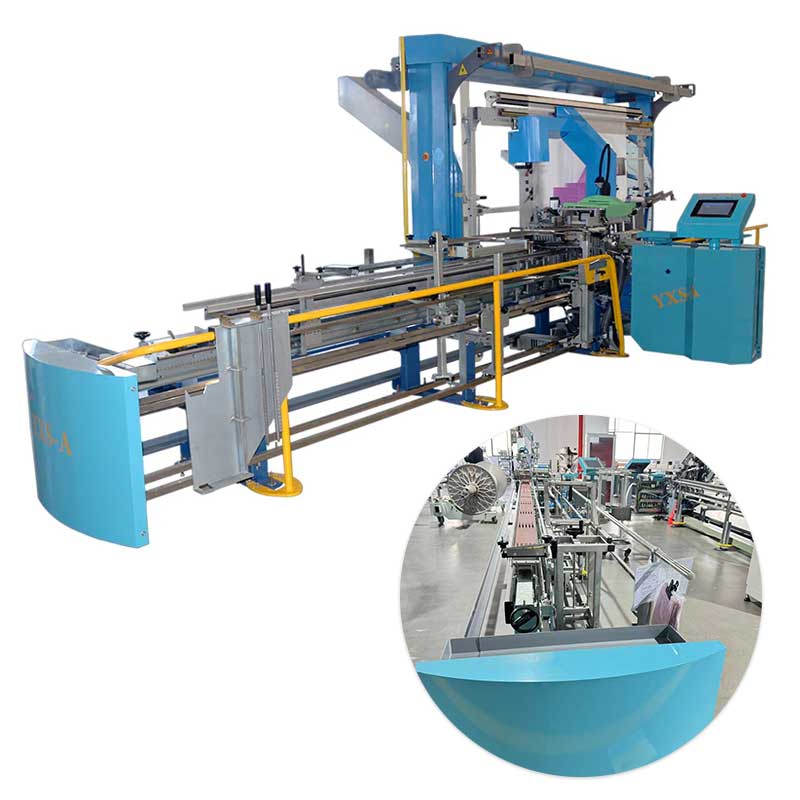

The advent of automatic drawing in machine has completely changed this situation. The equipment adopts a multi-station collaborative operation mode, equipped with high-resolution industrial cameras and a dedicated light source system. It can automatically identify thread positions, detect thread defects, and real-time plan the optimal threading path through AI algorithms. Its core precision manipulator adopts a bionic design, imitating the flexible movement of human fingers to achieve accurate grasping and threading of threads, with a movement accuracy of 0.1 mm.

Outstanding Highlights of Technological Innovation

The technological innovation of this equipment is mainly reflected in three aspects:

1. In the field of visual recognition, it adopts deep learning algorithms, which can adapt to yarns of different materials and colors, and accurately identify thread positions even in strong reflection or low-light environments.

2. In terms of mechanical control, a multi-axis linkage control system has been developed to ensure constant thread tension during the threading process and avoid thread breakage.

3. A comprehensive digital management platform has been established to monitor the operating status of the equipment in real time and realize predictive maintenance.

It is particularly worth mentioning that the equipment also innovative adopts a modular design, which can flexibly configure the number of threading stations according to customer needs to adapt to the production requirements of enterprises of different scales. At the same time, the equipment also has strong data collection and analysis capabilities, providing data support for production enterprises in process optimization and quality traceability.

Significant Economic Benefits, Promoting Industry Upgrading

Practical application data shows that the production efficiency of automatic drawing in machine reaches over 20,000 threads per hour, which is 5 to 8 times that of manual work, and it can realize 24-hour continuous operation. In terms of quality, the threading accuracy reaches more than 99.9%, greatly reducing weaving defects caused by threading errors. In addition, the equipment can also reduce labor costs by 70% and shorten training time by 60%, helping enterprises alleviate the pressure of skilled worker shortage.

At present, this technology has been put into use in a number of large-scale textile enterprises, covering cotton spinning, wool spinning, chemical fiber and other fields. User feedback shows that after using automatic drawing in machine, the first-grade product rate of products has increased by 3 to 5 percentage points, energy consumption has decreased by 15%, and the comprehensive production cost has dropped by more than 20%. These improvements not only enhance the market competitiveness of enterprises, but also provide strong support for the sustainable development of the industry.

Looking to the Future: A New Era of Intelligent Textiles

Industry experts said that the industrial application of automatic drawing in machine is an important milestone in the process of textile equipment. With the in-depth integration of new technologies such as 5G and industrial internet, warp threading equipment will develop in a more intelligent and flexible direction in the future. It is expected that within the next three years, the market penetration rate of automatic drawing in machine will reach more than 30%, driving profound changes in the production model of the entire textile industry.

This innovative technology not only improves the technical level of China's textile equipment manufacturing industry, but also provides a model for the transformation and upgrading of traditional industries. At the critical period of the reshaping of the global textile industry pattern, the breakthrough of automatic drawing in machine will strongly promote China's transformation from a large textile country to a powerful textile country, and contribute significantly to the realization of the strategic goal of "Made in China 2025".

With the continuous improvement of intelligence, automatic drawing in machine are becoming the core equipment for textile enterprises to build intelligent factories, promoting this traditional industry to move steadily towards the direction of high quality, high efficiency and sustainable development.

Please visit product page for more information

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts