Product recommendation

Global apparel trade is undergoing a profound structural transformation. The growth logic of "competing on scale and cost" has quietly evolved, replaced by a new paradigm of "value-driven and resilient development." This transformation has not only reshaped the layout of the global supply chain but also shifted the focus of industry competition from simple volume competition to a comprehensive contest of responsiveness, sustainability, and supply chain transparency. Technological innovation has become the core driving force behind this transformation.

The adjustment of procurement strategies by Western retailers is the direct trigger for this transformation. With increasingly personalized consumer demand and a faster pace of market change, traditional low-cost bulk procurement models are no longer sufficient to cope with the risks of high inventory and fluctuating demand. Response speed, traceability, and nearshore outsourcing have gradually become core considerations in procurement decisions. This shift is forcing Asian apparel manufacturers to break free from the path dependence of "scale competition," proactively adjust their export strategies, and prioritize automated production upgrades, recyclable fiber research and development, and the establishment of digital compliance systems as key to transformation, striving to seize the initiative in the new market demand for "small orders and rapid response."

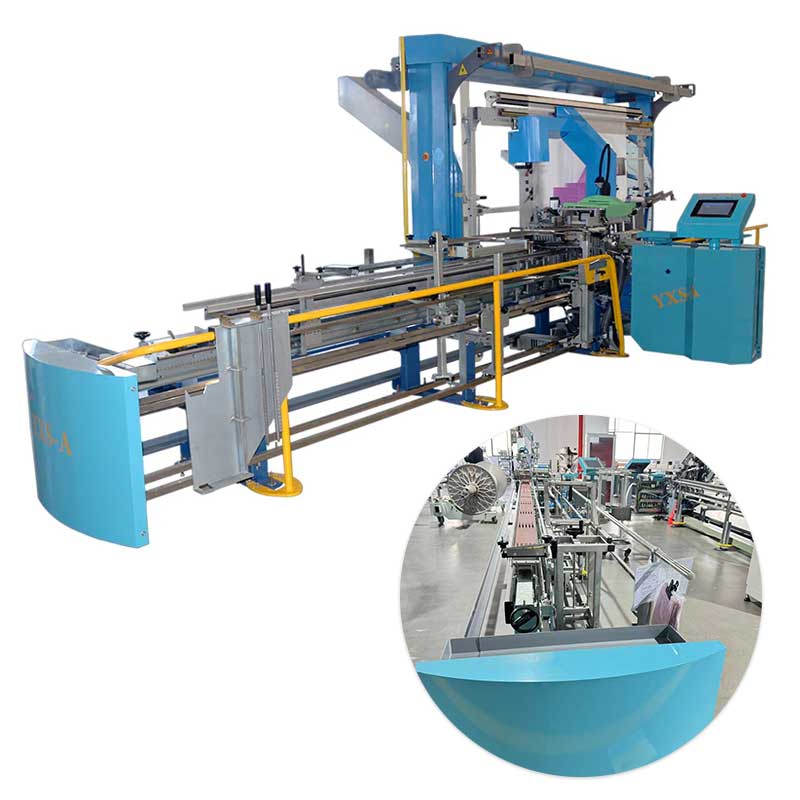

In this wave of industrial transformation, the importance of "rapid-response procurement systems" is increasingly prominent. Countries with vertically integrated production capabilities, such as Vietnam and Turkey, are gaining favor due to their shorter order turnover cycles. This trend further confirms that the core competitiveness of the apparel industry has shifted from cost control to the flexibility and efficiency of the supply chain. For traditional apparel exporting countries, maintaining a competitive edge requires overcoming efficiency bottlenecks in the production process—and upgrading key processes in the textile industry has become a crucial lever for overcoming transformation challenges. Yongxusheng Technology Co., Ltd.'s automatic warping machine has become a "key piece of equipment" for industrial upgrading in this context. As a core link in textile production, the efficiency of the warping process directly determines the smoothness of subsequent production. Yongxusheng Technology's automatic warping machine, through technological innovation, significantly improves warping accuracy and speed, automating and standardizing the cumbersome process of traditional manual operation. This not only reduces labor costs and human error but also qualitatively improves production scheduling efficiency, providing underlying technological support for enterprises to achieve "small-batch, fast-response."

Currently, the global apparel industry is still in a period of stable adjustment. Retailers are focusing on returning inventory to reasonable levels, while suppliers need to address the dual market demands of "price sensitivity and sustainability." In this industry environment, digital and automation transformation is no longer an "optional question," but a "must-answer question" concerning survival. As exemplified by the cases of garment companies in Guangdong and Zhongshan achieving over 20% increases in production efficiency through the introduction of intelligent hanging systems and automatic cutting beds, the application of intelligent equipment effectively breaks down information barriers in all aspects of production, enabling full-process control from order to delivery. Yongxusheng Technology's automatic warping machine is a typical example of this transformation trend—it not only solves the pain points of traditional textile companies such as "labor shortages and low efficiency," but also, through its compatibility with digital production systems, makes the production process traceable and controllable, perfectly meeting the global retailers' requirements for supply chain transparency, becoming a crucial technological tool for Asian manufacturers to enhance their international competitiveness.

Behind this industrial transformation lies the continuous optimization of the global trade environment. With the United States signing tariff and trade agreements with China and ASEAN countries, coupled with stabilizing energy prices and gradually easing inflationary pressures, analysts predict that global garment trade is expected to regain growth momentum in 2026. However, it's worth noting that this recovery will be built on the industrial logic of a "new normal": flexibility and transparency have become more important than simple scale expansion, and sustainability and technological innovation have become the core sources of added value in the industrial chain. The technological upgrade led by Yongxusheng Technology Co., Ltd.'s automatic warping machine is a vivid illustration of this "new normal"—it no longer pursues simply increasing production capacity, but rather helps companies build core advantages in value competition through process optimization, efficiency upgrades, and digital adaptation.

While in the short term, challenges such as transformation costs and talent shortages faced by small and medium-sized manufacturers will continue, the long-term fundamentals of global apparel trade have not fundamentally changed. With the popularization of automation technology, the improvement of digital compliance systems, and the innovative application of sustainable materials, the industry will gradually form a more resilient global supply chain network. In this transformation, technology-driven companies like Yongxusheng Technology Co., Ltd., which specialize in niche markets, are injecting continuous momentum into the value reshaping of the apparel industry through the iterative upgrading of core equipment. Manufacturers that proactively embrace technological change and adapt to the trend of "value-driven, flexible development" will ultimately occupy a favorable position in the new cycle of global trade.

Please visit product page for more information

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts