Product recommendation

In the process of Weaving Loom, our manufactured range of Drop wires play a vital role. It is a metal device through which a warp yarn is threaded. If in case of warp yarn breaks, that metal device falls and completes an electrical circuit, which stops the loom.

Usually, these drop wires are installed on the weaving loom to detect warp breakage. Offered array of Drop wires is also called a drop pin or dropper in many countries. It is a very crucial part of the shuttle less loom. Also, it shows warp breakage and gives an indication to warp stop motion to stop the weaving machine.

Drop Wires are manufactured in closed and open types for mechanical and electrical warp stop motion. These drop wires are made from hardened and tempered high carbon steel strips / stainless steel 420 J grade magnetic material. The drop wires are deburred to ensure smoothness and polished to minimize yarn frictions.

At our manufacturing unit, our highly qualified engineers manufacture these Drop wires by using top-notch quality of raw materials like Carbon Steel and Stainless Steel. In fact, our company procures these raw materials from reliable vendors so that our clients do not have any chance of complaining and the quality of the fabric can be enhanced without any loss.

Due to their best quality manufactured range of Drop Wires are highly demanded by our national and international clients. Precisely engineered in compliance with the industry set norms and regulations, offered array of drop wires are known for their sturdy construction, high tensile strength, and resistance to corrosion and longer functional life. In addition, our Drop Wires are widely used in imported and domestic rapier loom, air jet loom, and water jet loom.

Some other features are also mentioned here:

· Corrosion-resistance

· Smooth, abrasion resistant surface of eyelet

· Hardness HV410~510

· Longer functional life

· Accurately designed

DROP WIRES

Length : 80 mm to 268 mm

Width : 7 mm- 15 mm

Thickness : 0.2 mm – 1.00 mm

· Mechanical Wrap Stop Motion

· Electrical Warp Stop Motion

EXECUTION

· Stainless Steel (420 J Magnetic)

· Electro Nickel Plating

· Zinc Plating (with Unichrome Blue Finish)

· Golden Yellow Finish

Specification For Drop Wires

MO= MECHANICAL OPEN || MC= MECHNICAL CLOSE

EO= ELECTRICAL OPEN || EC= ELECTRICAL CLOSE

Drop wire weight | Length mm | Width mm | Thickness mm | weight gm |

MO/EO | 145 | 08 | 0.2 | 1.08 |

MO/EO | 165 | 08 | 0.2 | 1.2 |

MO/EO | 165 | 11 | 0.2 | 1.9 |

0.3 | 2.9 | |||

0.4 | 3.8 | |||

0.5 | 4.8 | |||

MC/EC | 165 | 11 | 0.2 | 2.2 |

0.3 | 3.3 | |||

0.4 | 4.4 | |||

0.5 | 5.5 | |||

MO/EO | 180 | 11 | 0.2 | 2.2 |

0.3 | 3.3 | |||

0.4 | 4.4 | |||

0.5 | 5.5 |

Stainless Steel Drop Pin | Weaving Looms Drop Pins | Mechanical Drop Pin | Rapier Loom Drop Pin | Sulzer Loom Drop Pin | Drop Wire For Weaving Looms | Drop Wires For Carpet Looms | Textile Industry Drop Pin | Airjet loom drop Pin | Weaving Loom Spare Parts Drop Pins

Please visit product page for more information

-

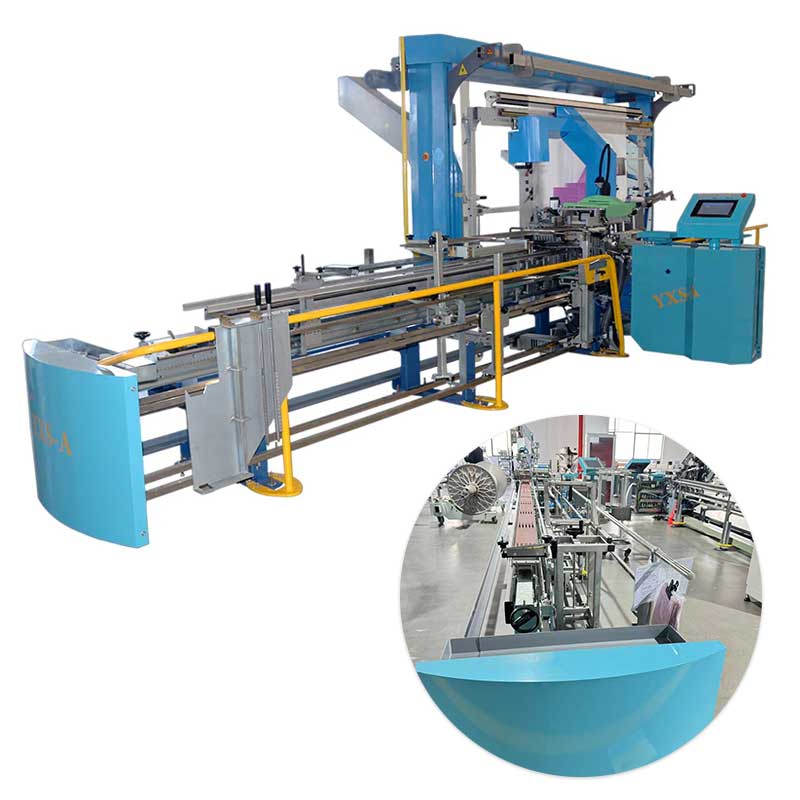

Weaving Heald Wire 331 Type C Simplex Column For Textile Production Industry

Yongxusheng Textile factory is committed to providing customers with the whole process service. From design, research and development to production and installation, we strictly control every link to ensure that every equipment meets the highest standards. Our professional team not only helps customers choose the right equipment, but also provides installation, commissioning and post-maintenance services. We focus on long-term relationships with our customers and help them achieve maximum production efficiency by providing high-quality products and professional services. Good Quality Machinery Textile Machine Spare Parts Western Metal Sea Item 331 Type C Simplex Column

More

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts