Product recommendation

In the long chain of textile production, the birth of fabric does not merely rely on the simple combination of yarn and loom. In the crucial process of yarn interweaving into cloth, seemingly small textile accessories such as drop wires, healds, and reeds are actually the "invisible framework" for the efficient operation of the loom. They directly determine the precision, quality, and production efficiency of the fabric, and are a core link that cannot be ignored in the transformation of the textile industry from "manufacturing" to "intelligent manufacturing".

Healds are the "planners" of fabric texture. Their core function is to guide the warp yarn to move up and down according to a preset pattern, creating a passage for the weft yarn to shuttle through. During the weaving process, each heald fixes one or a group of warp yarns. When the shedding mechanism of the loom drives the healds to rise and fall, the warp yarns will form a clear "shed" - this is the basis for the birth of different fabric weaves such as plain weave, twill weave, and satin weave. High - quality healds need to have extremely high wear resistance and toughness. Whether producing light - weight silk fabrics or thick denim, it is necessary to match the appropriate heald specifications according to the fineness of the warp yarn and the weaving speed. If the healds are deformed or broken, it may cause the warp yarns to be misaligned at best, and at worst, it may lead to "float" in the fabric, directly affecting the appearance of the product.

Drop wires are the "safety sentinels" of the loom, undertaking the key functions of warp - break detection and shutdown protection. They are usually hung below the warp yarns and connected to the loom's electronic control system. When a certain warp yarn breaks due to excessive tension, yarn quality defects, etc., the corresponding drop wire will fall without support, triggering a circuit switch and making the loom stop quickly. This process can not only prevent the production of "warp - missing" fabric caused by the breakage of the warp yarn, reducing the waste of raw materials, but also give operators time for maintenance and reduce the idle running loss of the equipment. In high - speed weaving scenarios, the sensitivity of the drop wire is particularly important. Its reaction speed is directly related to production efficiency and fabric qualification rate. Therefore, the industry has strict standard requirements for parameters such as the flatness and electrical conductivity of the drop wire.

Reeds are the "dimension - setters" for fabric formation, mainly responsible for two core tasks: First, it closely pushes each incoming weft yarn to the shed, ensuring that the weft density (the number of weft yarns per unit length) of the fabric meets the design requirements, determining the tightness and thickness of the fabric. Second, it combs the warp yarns to ensure that the warp yarns are evenly arranged during the weaving process and prevent the warp yarns from tangling with each other. Fabrics for different purposes have significantly different requirements for reeds: When producing high - count and high - density shirt fabrics, reeds with fine tooth pitches and hard materials are required to ensure uniform weft - beating tightness; while when producing thick canvas and geotextiles, the reeds need to have stronger impact resistance to prevent deformation caused by excessive weft yarn tension. In addition, the cleaning and maintenance of reeds are also crucial. If there are flying fibers and yarn scraps remaining between the reed teeth, it will cause warp yarn abrasion and uneven weft - beating, affecting the quality stability of the fabric.

With the transformation of the textile industry towards intelligence and high - end, these traditional textile accessories are also constantly upgrading. Nowadays, healds and drop wires made of new materials such as carbon fiber and high - strength alloys have emerged on the market. They are lighter in weight and more wear - resistant, and can adapt to higher weaving speeds. Reeds, through precision CNC processing technology, have achieved smaller tooth - pitch errors and higher surface smoothness, meeting the strict requirements of functional fabrics (such as waterproof and breathable fabrics) for weaving precision. At the same time, some high - end looms have integrated the accessory status monitoring function into the electronic control system, and through sensors, they can collect the operation data of drop wires and reeds in real - time, realizing fault warning and intelligent maintenance, and further improving production efficiency.

From a single yarn to a bolt of fabric, accessories such as healds, drop wires, and reeds are like the "capillaries" of the loom. Although they are not as eye - catching as the main body of the loom, they connect every key link in the weaving process. Their quality and performance are not only the basis for textile enterprises to control costs and enhance product competitiveness, but also an important support for promoting the transformation of the industry from "scale production" to "quality production". In the future, with the continuous integration of new materials and new technologies, these "invisible frameworks" will continue to radiate new vitality and inject more impetus into the high - quality development of the textile industry..

Please visit product page for more information

-

280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

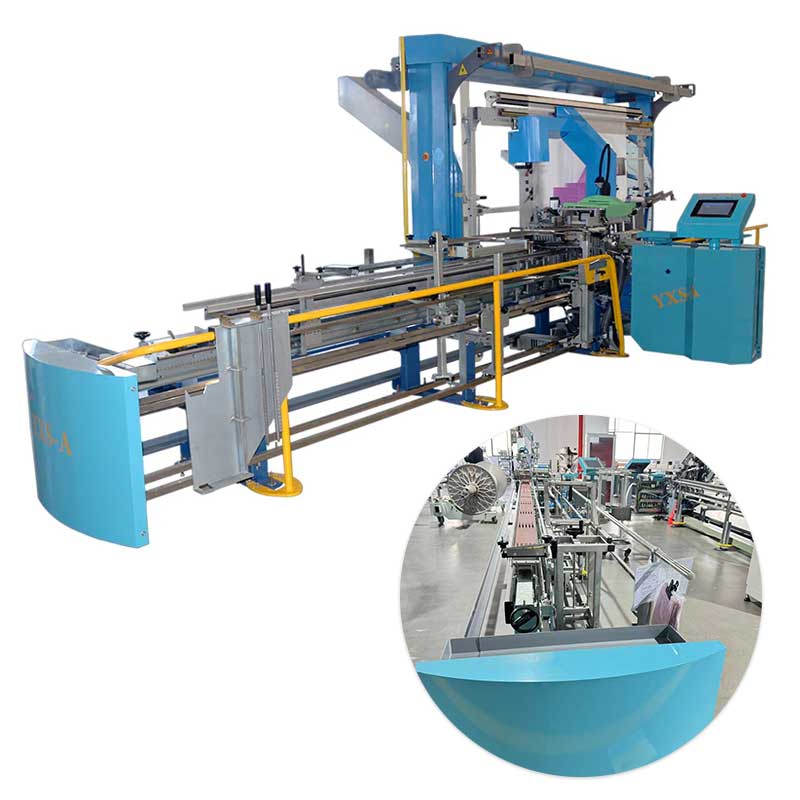

Yongxusheng Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad. We always adhere to the concept of leading technology, and constantly promote product innovation and upgrading. Through cooperation with global customers, we have accumulated valuable market experience and continuously optimize product design and production processes. In the future, Yongxusheng will continue to expand the international market, enhance the global competitiveness of products, so that more customers can enjoy our quality services. Hot Sales Strict Material Selection Heald Wires For Weaving Machine Spare Parts

More

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts