Product recommendation

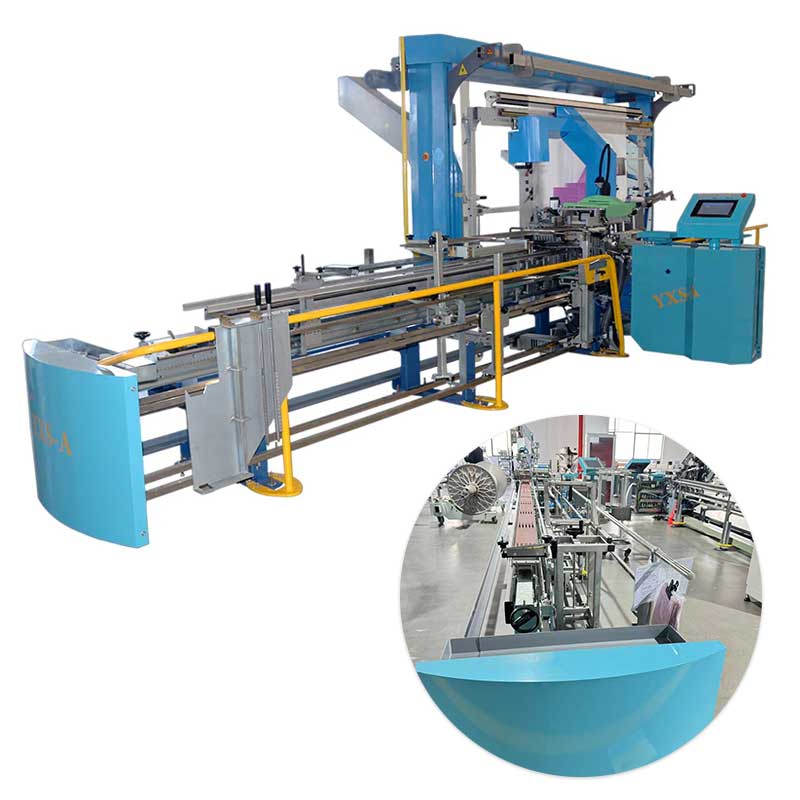

In the textile industry, the efficiency and precision of production processes are paramount. One critical component that plays a significant role in this regard is the drop wire, which works in conjunction with the heald to ensure smooth operations during weaving. The factory has professional production lines and advanced processing equipment, which can efficiently and accurately manufacture drop wires of various specifications. This capability is essential for meeting the diverse needs of textile manufacturers.

Drop wires are integral to the weaving process, as they help in the fixation and traction of the warp wire. When combined with healds, which are used to separate and lift the warp threads, drop wires facilitate the automatic threading machine's ability to perform its tasks seamlessly. The precision in manufacturing drop wires ensures that they can withstand the rigors of high-speed weaving, maintaining the integrity of the fabric being produced.

The advanced processing equipment utilized in the factory allows for the production of drop wires that meet stringent quality standards. This not only enhances the durability of the wires but also minimizes the risk of operational disruptions during the textile process. By ensuring that the drop wires are manufactured to exact specifications, the factory supports the automatic threading machine in completing the fixation and traction of the warp wire with ease.

Moreover, the ability to produce drop wires in various specifications means that textile manufacturers can customize their production lines according to specific requirements. This flexibility is crucial in an industry that demands adaptability to changing market trends and consumer preferences.

In conclusion, the synergy between drop wires and healds, supported by professional production lines and advanced processing equipment, is vital for the efficiency of textile manufacturing. By ensuring high-quality drop wires, factories can enhance the overall productivity and quality of the fabrics produced, ultimately contributing to the success of the textile industry.

Please visit product page for more information

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts