Product recommendation

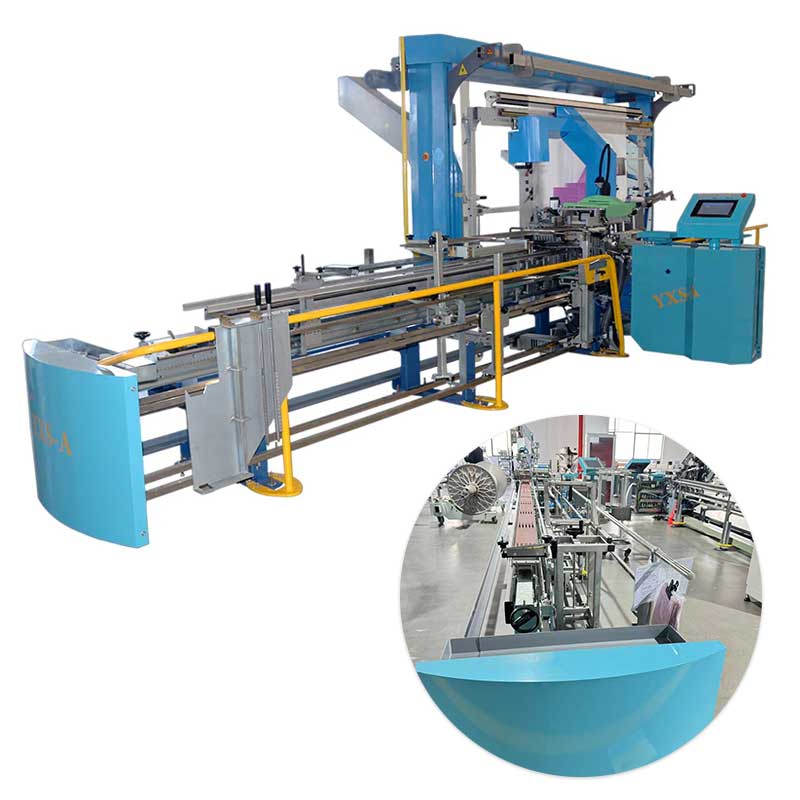

The warp drawing machine is a textile machine that is mainly used to pass the warp yarn through the dropper, heald and reed to prepare for the weaving process.

The basic structure and working principle of the warp drawing machine are as follows:

Structural composition. The warp drawing machine usually includes a fixed bottom plate, a transmission box, a drive motor, a yarn drawing plate, a heating straightener, a yarn feeding roller, a belt box, a yarn drawing driven roller, a tension roller shaft and a yarn delivery plate. These components work together to achieve the functions of guiding, heating and straightening, feeding and yarn delivery of the warp yarn.

Working principle. The working process of the warp drawing machine involves multiple steps, including guiding, heating and straightening, feeding and drawing of the warp yarn. Specifically, the warp yarn is drawn out from the warp beam, heated and straightened by the heating straightener inside the yarn drawing plate, and then sent to the drawing position through the yarn feeding roller. Here, the warp yarn is guided through the dropper, heald and reed to complete the drawing process. During the whole process, the drive motor drives the various components to work together through the transmission box to ensure that the warp yarn can pass smoothly through the predetermined position.

Technical features. Modern warp drawing machines mostly adopt modular design and can be customized according to customer needs. For example, according to different fabric types, warp drawing machines can be divided into many types, such as ordinary automatic warp drawing machines, warp drawing machines suitable for denim and bedding, and warp drawing machines suitable for high-end shirt fabrics and outerwear. These different types of warp drawing machines have different technical characteristics and application scopes to meet different production needs. 2

Automation development. With the development of science and technology, warp drawing machines have gradually realized automation and intelligence. For example, automatic warp drawing machines can be controlled by computer programs to realize automatic warp drawing of warp yarns, greatly improving production efficiency and weaving quality. These devices not only reduce labor intensity, but also improve production efficiency and product quality, and are widely used in the textile industry.

In summary, the warp drawing machine realizes the automatic warp drawing process of warp yarns through its specific structure and working principle, and is an indispensable and important equipment in the textile industry.

Please visit product page for more information

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts