Innovative Automatic Drawing Machine Revolutionizes Production of Drop Wire and Heald Wire Knitting Heald

2025-07-25

The recent launch of a cutting-edge automatic drawing machine has marked a significant leap forward in the manufacturing sector, particularly for components critical to textile and industrial weaving—most notably drop wire, heald wire, and knitting heald. This state-of-the-art equipment, designed to enhance precision and efficiency, is set to redefine production standards for these essential parts.

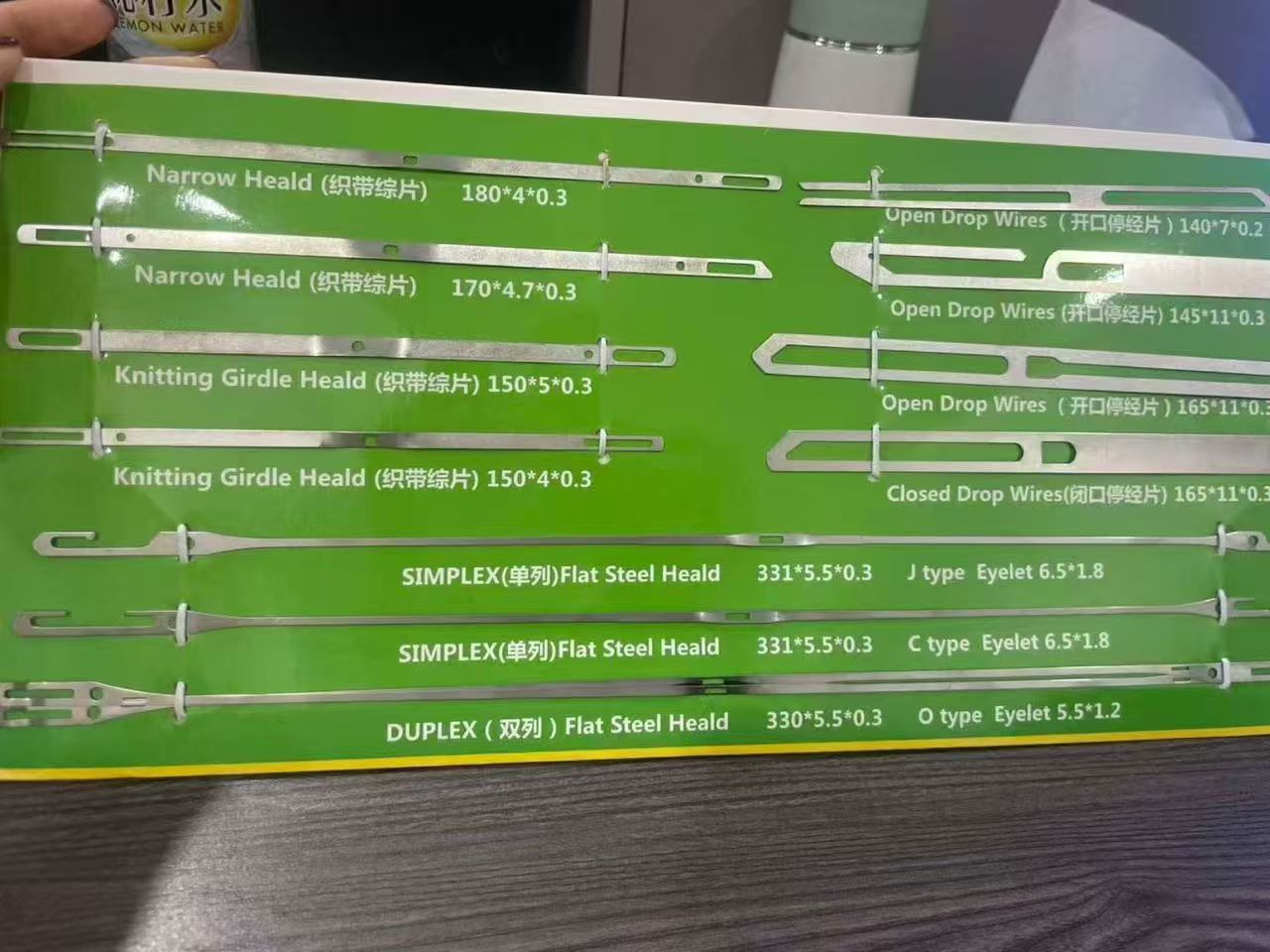

At the core of this advancement is the machine’s ability to streamline the creation of drop wire, a small yet vital component that ensures smooth thread movement in looms. Unlike traditional methods, which often rely on manual adjustments and face challenges with consistency, the new technology produces drop wire with unparalleled accuracy, reducing waste and boosting output. Manufacturers report that the drop wire produced now meets stricter quality benchmarks, with fewer defects and improved durability, making it a preferred choice for high-performance weaving operations.

Equally transformative is the machine’s impact on heald wire production. Heald wire, a thin, rigid wire used to separate and guide threads during weaving, demands exceptional uniformity to prevent thread breakage and ensure seamless operation. The automatic system’s precision engineering allows for the mass production of heald wire with consistent thickness and tensile strength, addressing long-standing industry pain points. Weavers using this heald wire note a noticeable reduction in downtime, as the reliable performance of the wire minimizes interruptions caused by misalignment or wear. This improvement not only enhances productivity but also lowers maintenance costs, making heald wire from this process a cost-effective solution for both small-scale workshops and large manufacturing facilities.

The knitting heald, another key component in textile machinery, has also benefited greatly from the new technology. Knitting healds require intricate shaping to interact smoothly with yarns, and the automatic drawing machine excels at replicating these complex designs with repeatable precision. By automating the shaping process, the machine ensures that each knitting heald adheres to exact specifications, eliminating variations that can compromise fabric quality. Textile producers highlight that the knitting healds now offer better yarn control, resulting in fabrics with more consistent textures and patterns. This consistency has become a selling point for manufacturers, as brands increasingly prioritize high-quality outputs to meet consumer demands.

Industry experts emphasize that while the automatic drawing machine is a game-changer, its true value lies in how it elevates the performance of drop wire, heald wire, and knitting heald as a cohesive system. When these components work in harmony—with drop wire guiding threads, heald wire maintaining alignment, and knitting heald ensuring precise yarn interaction—weaving processes become significantly more efficient. Factories already using the machine report a 30% increase in daily production volumes, with a 25% reduction in material waste, underscoring the tangible benefits of integrating this technology into existing workflows.

As the textile industry continues to evolve, driven by demands for faster production and higher quality, innovations like this automatic drawing machine are set to play a pivotal role. By enhancing the reliability and performance of drop wire, heald wire, and knitting heald, manufacturers are better equipped to meet market needs, setting new standards for excellence in weaving and knitting operations worldwide.