Product recommendation

Recently, with the continuous growth of the textile industry's demand for efficient and high-quality production, technological innovations in the knitting heald – a key component of webbing looms – have become the focus of the industry. The application of the new-type knitting heald has significantly improved the performance of high-speed shuttleless webbing looms, bringing higher production efficiency and product quality to webbing manufacturers.

As an important part of fabrics, webbing is widely used in clothing, luggage, decoration and other fields. Traditional webbing looms face problems such as low efficiency and unstable product quality during production. The emergence of high-speed shuttleless webbing looms has brought new development opportunities to the industry. Among them, the knitting heald, as the core component controlling the movement of warp yarns, its performance directly affects the overall performance of the webbing loom.

After years of research and development, the technical team of Hangzhou Qiaoxing Machinery Factory has successfully launched a new-type knitting heald suitable for high-speed shuttleless webbing looms. This knitting heald adopts advanced design concepts and high-quality materials, effectively solving the problems of stability and durability of traditional knitting healds under high-speed operation.

In terms of structural design, the new-type knitting heald optimizes the mechanical structure of the heald frame, using high-strength aluminum alloy material, which reduces weight while improving the rigidity of the heald frame. Through innovative design of the arrangement and shape of heald wires, the frictional resistance of warp yarns during movement is reduced, and the occurrence of yarn breakage is decreased. In addition, the knitting heald is equipped with an intelligent adjustment system, which can automatically adjust the height and angle of the heald frame according to different webbing varieties and process requirements, ensuring more precise movement of warp yarns.

After introducing this new-type knitting heald, Xuzhou Qixing Machinery Co., Ltd. has seen a significant improvement in the production efficiency of its high-speed shuttleless webbing looms. According to the person in charge of the company: "After using the new-type knitting heald, the speed of our webbing looms has increased by 30%, and the defective rate of products has decreased by 15%. This not only improves our production capacity but also reduces production costs and enhances the competitiveness of our products in the market."

Industry experts stated that the application of the new-type knitting heald is an important breakthrough in the technical development of webbing looms. It not only improves the performance of high-speed shuttleless webbing looms but also lays the foundation for the intelligent and automated development of the webbing industry. With the continuous maturity and promotion of related technologies, it is expected that high-speed shuttleless webbing looms will be more widely used in the webbing production field in the next few years, driving the entire industry to a higher level of development.

Please visit product page for more information

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts

-

- The journey of deepening the textile accessories business of Changzhou Yongxusheng Technology Co., Ltd.

- Innovation Drives Textile Efficiency Revolution: New Generation Intelligent Leno device Leads Industry Upgrade

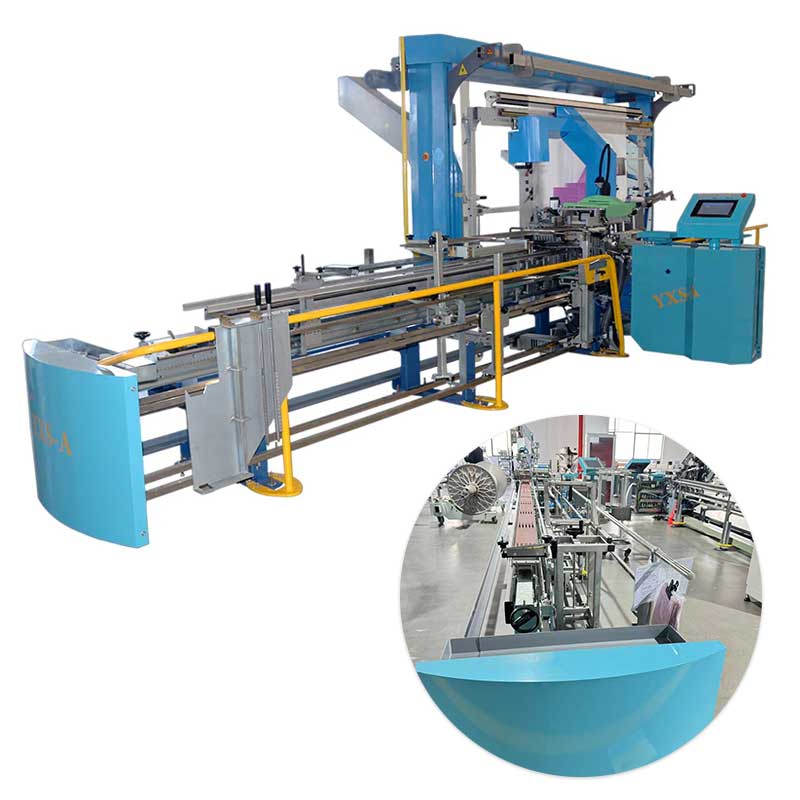

- Fully Automatic Drawing Machine Lead the Textile Industry into a New Era of Efficiency and Precision

- Automatic Drawing-in Technology Achieves Substantial Breakthrough, Helping Textile Enterprises Overcome "Labor Shortage" and "Quality Challenges"