Automatic Drawing-in Technology Achieves Substantial Breakthrough, Helping Textile Enterprises Overcome "Labor Shortage" and "Quality Challenges"

2025-11-19

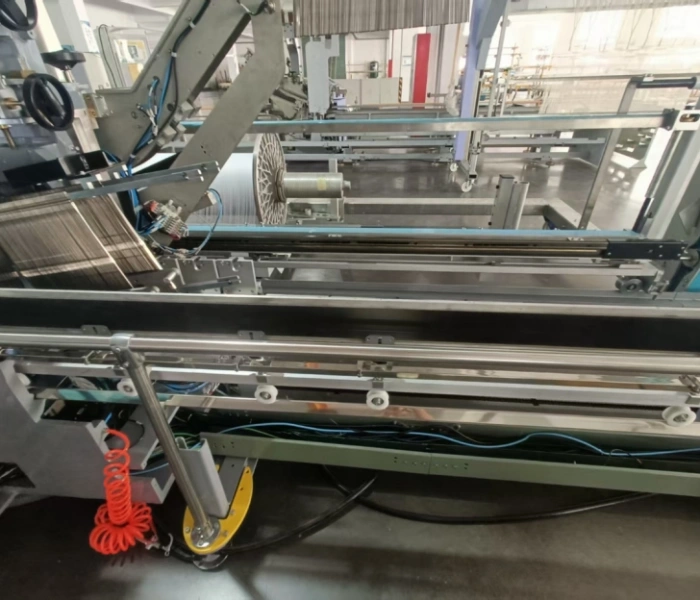

In recent years, against the backdrop of the textile industry's continuous advancement in intelligent transformation and digital transition, automatic drawing-in technology, a crucial part of the weaving preparation process, has moved from the laboratory to the production floor, becoming important equipment for addressing the actual pain points of enterprises. Journalists have learned from within the industry and multiple equipment suppliers that the stability, applicability, and cost-effectiveness of domestic automatic drawing-in machines have been verified, and they are entering a period of accelerated market application.

Addressing Industry Pain Points: The Inevitable Shift from "Man" to "Machine"

The drawing-in process requires threading thousands to tens of thousands of warp yarns sequentially through drop wires, heddles, and reed dents. This was once one of the most skill-intensive and heavily reliant-on-skilled-workers roles in the textile mill.

"Training an excellent drawing-in worker takes one to two years. The labor intensity is high, young people are unwilling to do it, and experienced workers are retiring year by year. The 'labor shortage' is our biggest challenge," stated a workshop supervisor from a Zhejiang textile enterprise, highlighting a common industry dilemma. Furthermore, manual drawing-in speed is limited (skilled workers average about 20-25 ends per minute), and prolonged work easily leads to fatigue, resulting in misdraws, missed ends, which directly affect subsequent weaving efficiency and fabric quality, causing material waste.

Steady Technological Progress: Machine Vision and Precision Execution are Key

Compared to early conceptual products, mainstream domestic automatic drawing-in machines have now resolved most of the core challenges. Their technological core lies in:

· High-Precision Machine Vision: Utilizing industrial cameras and multi-light source cooperation to accurately identify yarns, drop wire eyes, heddle eyes, and reed dents, providing "eyes" for subsequent actions.

· Multi-Axis Coordinated Control: Using servo motors and precision motion control to drive the threading mechanism through a series of actions like grabbing, dividing yarns, leading, and inserting, replacing human hands and eyes.

· Continuous Adaptive Optimization: Equipment manufacturers continuously optimize recognition algorithms for different yarn materials (such as cotton, linen, chemical fiber) and different yarn colors, enhancing the equipment's universality.

According to a technical lead from a leading domestic automatic drawing-in machine manufacturer: "Our third-generation model, when handling conventional cotton yarn varieties, can stably achieve a drawing-in speed of 40-50 ends per minute, about 1.5 to 2 times the efficiency of a skilled worker, and it can operate continuously, significantly improving loom utilization rates."

Benefits Verified: Multiple Improvements in Efficiency, Quality, and Management

Enterprises that have already deployed this equipment on a large scale in production are reaping tangible benefits.

· Efficiency and Cost-Benefit: A responsible person from Jiangsu Deshun Textile Co., Ltd. calculated: "One automatic drawing-in machine can replace 3-4 drawing-in workers. Although the initial equipment investment is substantial, considering the rising labor costs, social security expenses, and personnel stability, the investment payback period is approximately 2-3 years. It's a cost-effective investment in the long run."

· Quality Stability: "The machine doesn't get tired. As long as the parameters are set correctly, it guarantees extremely high drawing-in accuracy," feedback from the quality inspection department of Shandong Hualong Textile indicated. "Since using the automatic drawing-in machine, the defect rate in weaving caused by drawing-in errors has decreased by over 80%, and fabric quality is more stable and controllable."

· Management Optimization: As part of the digital workshop, the automatic drawing-in machine can record production data, enabling process traceability and providing a data foundation for refined enterprise management.

Challenges and Future: Moving Towards Higher Speed and Broader Adaptability

Although the technology is maturing, the industry consensus is that automatic drawing-in machines still have room for improvement in speed and stability when dealing with ultra-high density, complex patterns, or special materials (such as very fine, low-elasticity, or yarns with high hairiness). Future R&D directions will focus on further increasing speed, reducing failure rates, and enhancing adaptability to complex processes.

Conclusion

The large-scale application of automatic drawing-in machines is a microcosm of the progress in China's textile equipment manufacturing industry. It tangibly addresses the core pain points faced by textile enterprises in the "post-demographic dividend" era. Its promotion is no longer an optional "whether or not" question but an inevitable path for enterprises to enhance competitiveness and achieve sustainable development. With the continuous iteration of technology and further optimization of costs, the automatic drawing-in machine is expected to become a standard configuration in modern weaving workshops.