Product recommendation

When the fabric glides off the loom, it is no longer yarn but a piece of mass-producible silence. Not a single protruding fibre is visible under a standard 600 lux beam; the surface shows a uniform matte—this is the ex-works condition of the latest 2.8 m-wide, 200 ends/cm high-count satin bedding fabric from Jiangsu Mingyuan Home Textiles. The zero-defect outcome was not decided by the final inspection, but by an order written long before the 14 000 parallel ends were still resting on the warp beam: an automatic drawing-in machine threaded every drop wire, heald wire and reed wire in one pass, compressing tolerances to 0.02 mm and embedding the gene of silence into high-speed weaving.

1. The Rehearsal on the Warp Beam

02:30, lights dimmed to 30 %. A Stäubli SAFIR S80 works the night shift unattended. Machine vision identifies colour and twist of every end at 160 ends/min; Active Warp Control 2.0 compares the data in real time, rejecting any yarn whose shade deviates by 0.3 %. Twin-servo motors in the drop-wire module run each stainless plate through a caliper check; any thickness beyond 0.005 mm is discarded on the spot. Before a heald wire is allowed to accept a yarn, an IR beam scans the eye for burrs invisible to the naked eye. In 8 hours the machine composes a four-layer warp score out of 48 000 ends, a symphony that will not miss a single note.

2. Silence in the Weaving Zone

08:00, the beam is rolled onto an OptiMax-i3.0S loom. The clearance between reed wire and heald wire is set to the physical minimum; at 600 rpm the friction between heald wire and drop wire is only 55 dB—quieter than an air-conditioner. Ruyi 420J2 stainless heald wires present a mirror-smooth channel, letting yarn tension fluctuate by merely 0.1 g during high-speed shedding. Ends break 0.3 times per 100 000 picks. The plant no longer crackles with snap alerts; only the steady bass hum of the loom remains—the most audible side effect of the upgrade: noise has vanished.

3. Ciphers at the Finishing Gate

16:00, the grey fabric enters finishing. Because potential yarn damage was virtually eliminated upstream, singeing needs only one pass to reach grade-4 smoothness, saving 30 % natural gas. On the sanforiser the cloth runs at 18 m/min with a skew kept under 0.5 %—no manual stenter is required. When the roll is finally batched, no trace of “lettuce edges” can be found. An RFID tag is auto-applied, encoding the drawing-in batch, heald-wire lifetime and drop-wire thickness—data ciphers for any future flaw trace-back.

4. Echoes in the End Market

Three weeks later the fabric is sewn into luxury hotel bedding and laid in a newly opened suite on Shanghai’s Bund. The guest’s first-night review reads: “Sheets make almost no rustle; no static crackle when turning.” The sentence is scraped by the system and pinged back to Mingyuan’s cloud. An engineer opens the dashboard; the curve for the drawing-in batch, the serial numbers of the heald wires and the thickness profile of the drop wires light up in unison. The silence of a single piece of cloth had already been written into its genes when it was still a field of parallel ends on the warp beam.

Please visit product page for more information

-

280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

Yongxusheng Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad. We always adhere to the concept of leading technology, and constantly promote product innovation and upgrading. Through cooperation with global customers, we have accumulated valuable market experience and continuously optimize product design and production processes. In the future, Yongxusheng will continue to expand the international market, enhance the global competitiveness of products, so that more customers can enjoy our quality services. Hot Sales Strict Material Selection Heald Wires For Weaving Machine Spare Parts

More

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts

-

- The journey of deepening the textile accessories business of Changzhou Yongxusheng Technology Co., Ltd.

- Innovation Drives Textile Efficiency Revolution: New Generation Intelligent Leno device Leads Industry Upgrade

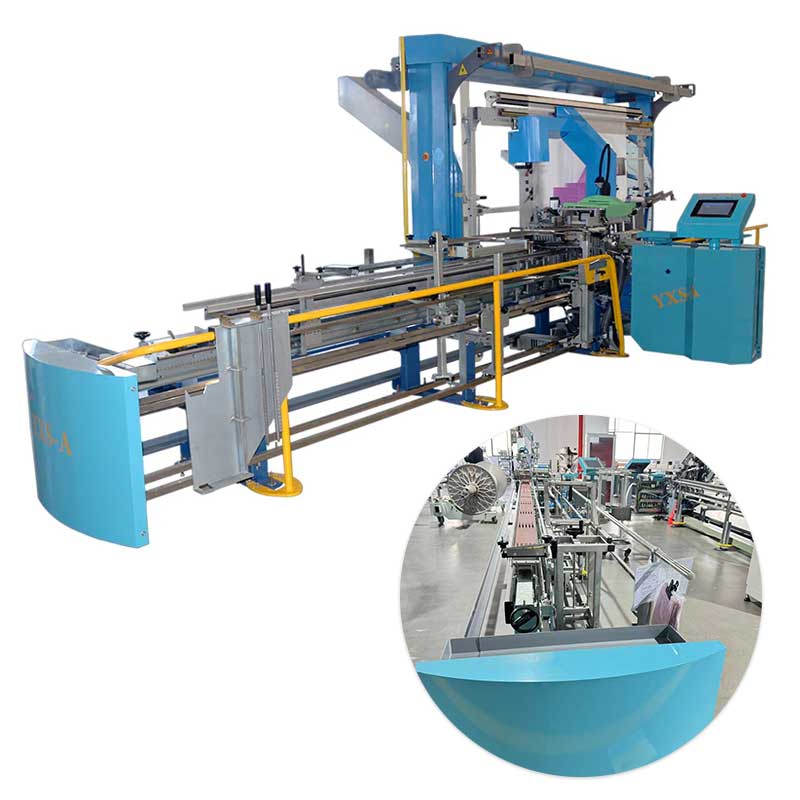

- Fully Automatic Drawing Machine Lead the Textile Industry into a New Era of Efficiency and Precision

- Automatic Drawing-in Technology Achieves Substantial Breakthrough, Helping Textile Enterprises Overcome "Labor Shortage" and "Quality Challenges"