Healds: Linking Supply and Demand in the Textile Market

2025-07-27

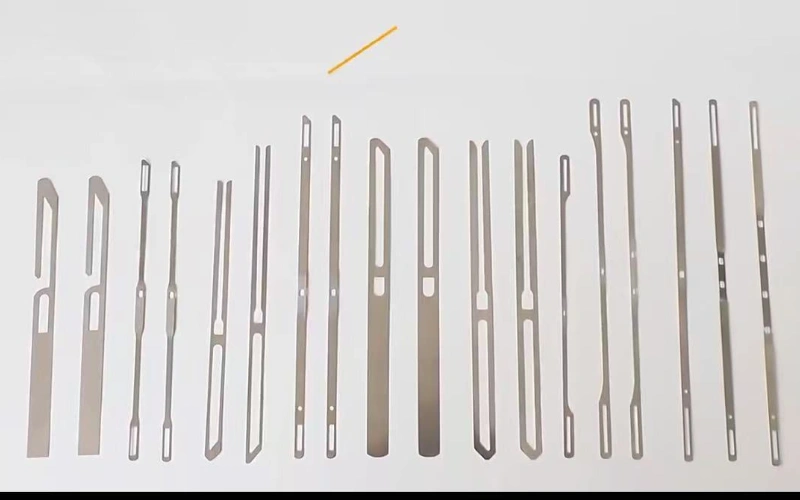

In the textile industry chain, healds, though seemingly basic accessories, act as "small components" that drive a "large market". They serve as a critical link connecting upstream manufacturing and downstream weaving demands, playing an indispensable role in the smooth operation of the entire industry.

Currently, with the surging demand for high-density and wear-resistant fabrics in niche markets such as home textiles and industrial fabrics, downstream weaving enterprises have significantly raised their requirements for healds in terms of precision and wear resistance. In response, upstream accessory manufacturers have carried out targeted upgrades: they adopt aviation-grade alloy materials to enhance the strength of healds, enabling them to withstand the high tension and frequent friction from warp yarns during high-speed weaving. Meanwhile, the application of nano-coating technology reduces the friction loss between healds and yarns, ensuring that even when processing tough materials like chemical fibers and blended fabrics, the yarns remain intact, thus improving the qualification rate of finished fabrics. These upgrades allow healds to perfectly adapt to high-speed looms and multi-material weaving scenarios, precisely meeting the market's demand for "efficient production".

At the same time, the collaboration between standardized healds and equipment such as automatic threading machines and heald frames has brought tangible benefits to small and medium-sized textile factories. Standardized healds, with uniform specifications and precise dimensions, can be seamlessly integrated with automatic threading machines, greatly improving threading efficiency. When used in conjunction with high-precision heald frames, they ensure stable movement of healds during the weaving process, reducing the frequency of machine shutdowns caused by heald displacement or damage. This not only helps enterprises reduce labor costs and accessory replacement expenses but also accelerates the industry's transformation from "labor-intensive" to "intelligent and efficient".

Industry insiders point out that the technological iteration of healds and their precise alignment with market demands are not only optimizing the production efficiency of individual enterprises but also laying a solid foundation for the high-quality development of the entire textile industry. As a "hidden link" in the industrial chain, healds will continue to play a key role in promoting the upgrading of textile manufacturing and meeting diversified market demands.