Research on Technological Development and Market Applications of Drop Wire - A Critical Textile Equipment Component

2025-07-26

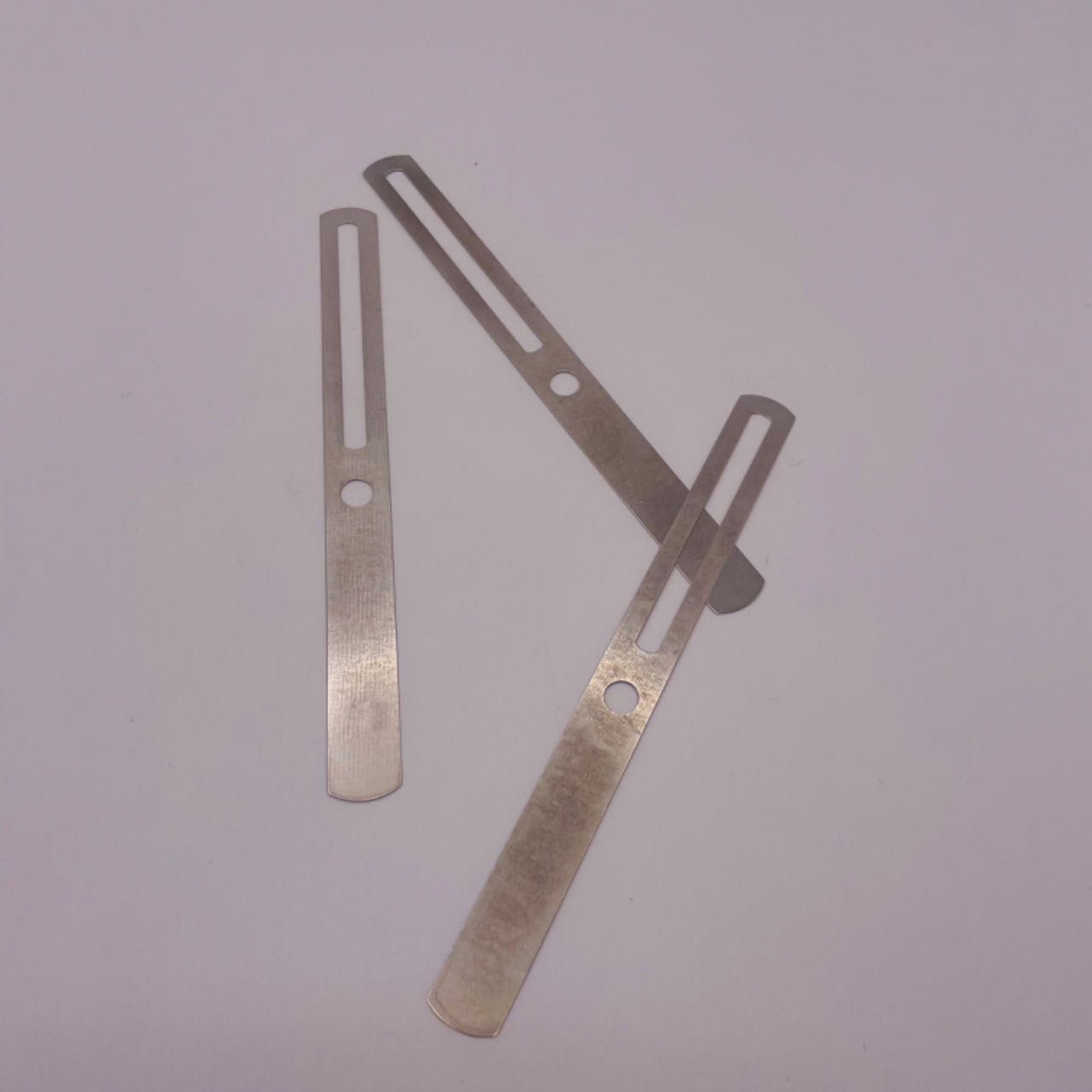

Drop Wire (warp stop motion) serves as an essential functional component in modern looms, playing an indispensable role in textile production. This paper explores the current development and future trends of Drop Wire from three dimensions: technical characteristics, material evolution, and market applications.

1、Technical Principles and Functional Features

Drop Wire is the core component of a loom's warp stop mechanism, operating by detecting changes in warp tension to trigger machine stoppage. Modern Drop Wires are manufactured using precision stamping processes, with weight tolerance controlled within ±0.01g to ensure sensitive yarn break detection. As loom speeds exceed 1200 rpm, higher demands are placed on the dynamic balance of Drop Wires.

2、Material Innovations and Advancements

Traditional galvanized steel is gradually being replaced by stainless steel and ceramic materials. 304 stainless steel Drop Wires can last over 5 years, while ceramic materials exhibit excellent wear resistance (friction coefficient <0.1). The latest composite Drop Wires combine metal strength with plastic damping properties, demonstrating outstanding performance in high-speed looms.

3、Intelligent Upgrade Trends

IoT technology is driving the intelligent evolution of Drop Wires:

- Integrated micro-sensors enable real-time warp tension monitoring.

- RFID tags facilitate production data traceability.

- Some high-end products feature self-diagnostic capabilities.

These innovations reduce downtime by over 30%, significantly improving weaving efficiency.

Conclusion:

The technological evolution of Drop Wire reflects the intelligent transformation of the textile industry. In the future, the integration of materials science, precision manufacturing, and digital technology will continue to drive innovation in this field.