Product recommendation

In March, CCTV's "News Network" told the story of the renewal of Shengze Textile Town, and "Morning News" used 11 minutes to tell the vivid practice of Shengze Textile's renewal of traditional industries with new quality productivity; in April, CCTV2's "Economic Information Network" focused on Shengze enterprises buying equipment and increasing production capacity with the help of the national style craze; in May, the People's Daily published an article on page 02 that once again brought people's attention to Shengze's new materials industry...

Shengze has never lacked the spotlight, vitality, or opportunities. As CCTV reported in March, more than 100 textile factories in this famous textile town are busy building factories and replacing machines, which is also the norm for the organic renewal of Shengze's industries in recent years.

In Shengze, the concept that a worker must sharpen his tools before he can do his job well has been deeply rooted in the minds of all operators. In recent years, the organic renewal project of Shengze's textile industry has been carried out in full swing, and many typical examples have emerged.

Since 2021, Suzhou Yishuang New Materials Co., Ltd. has started intelligent transformation. That year, the company carried out organic renewal of the original 12,000 square meters of factory buildings, eliminated all the original old equipment, and updated it to an intelligent and automated yarn production project. In June 2023, the first phase of Yishuang New Materials' organic renewal project was officially put into production, introducing 78 Japanese Murata vortex spinning machines, automatic warp drawing machines, etc., and supporting 160 sets of German Truetzschler pre-spinning equipment, 20 sets of auxiliary equipment such as automatic packaging lines, and will achieve an annual output of 50,000 tons of high-quality yarn, with an estimated annual output value of more than 600 million yuan. In addition, the project has realized automatic networking and workshop intelligent production, intelligent lighting, and intelligent handling. It uses static vortex tubes to form yarn, cancels a large number of high-speed rotating parts, and greatly improves production efficiency. It is understood that the company's second phase project is already under construction, and will introduce 102 Japanese Murata vortex spinning machines. It is expected to be fully put into production in 2025. By then, it will further improve production efficiency and expand production capacity. The annual output value is expected to double again, further promoting the company from traditional weaving to professional spinning.

When we systematically sort out these renewal projects, it is not difficult to find that Shengze textile enterprises do not seem to be stingy in their investment in equipment, and the demand for excellent high-end equipment is still there. And these cases are just the tip of the iceberg of the organic renewal of the industry in the region, but they are indeed the best proof of the vitality of the Shengze market. This vitality is a business opportunity that textile machinery enterprises cannot miss.

Please visit product page for more information

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts

-

- The journey of deepening the textile accessories business of Changzhou Yongxusheng Technology Co., Ltd.

- Innovation Drives Textile Efficiency Revolution: New Generation Intelligent Leno device Leads Industry Upgrade

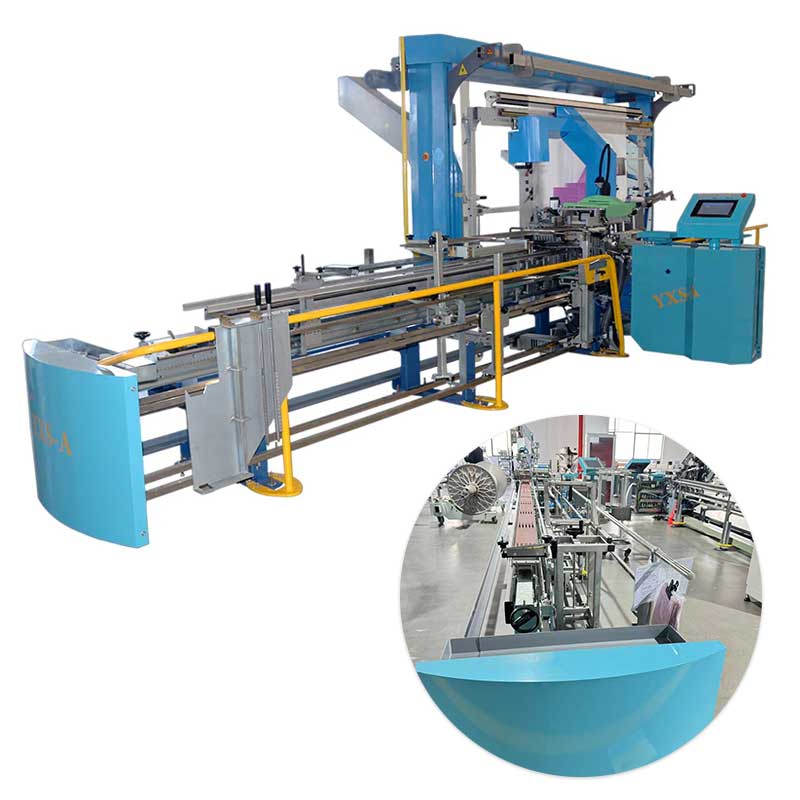

- Fully Automatic Drawing Machine Lead the Textile Industry into a New Era of Efficiency and Precision

- Automatic Drawing-in Technology Achieves Substantial Breakthrough, Helping Textile Enterprises Overcome "Labor Shortage" and "Quality Challenges"