Product recommendation

A breakthrough has recently emerged in the domestic textile machinery sector—after years of technological, a new generation intelligent Leno device, integrating three core advantages of high-precision control, low energy consumption, and adaptability to diverse fabrics, has officially entered mass production and been launched in the market. Developed jointly by leading industry enterprises and research institutions, this product thoroughly addresses industry pain points such as easy thread slippage in high-speed weaving, complex debugging, and high energy consumption commonly found in traditional Leno devices, providing key technical support for textile enterprises to reduce costs and improve efficiency.

As an important component of the manufacturing industry, the textile industry relies heavily on the Leno device, a core accessory of looms that directly determines the quality of fabric edges, weaving stability, and production efficiency. Traditional products often encounter issues like loose edges, high yarn breakage rates, and insufficient adaptability when dealing with complex weaving scenarios such as high-count and high-density fabrics or elastic fibers, becoming a "bottleneck" that restricts the production capacity improvement of textile enterprises.

The new generation intelligent Leno device achieves breakthroughs through three major technological innovations: it employs a servo motor for precise control of yarn tension, with errors kept within ±0.1N, ensuring uniform and smooth edge weaving during high-speed operation; it is equipped with an intelligent energy consumption optimization system, saving over 30% more energy compared to traditional products, with annual electricity cost savings exceeding ten thousand yuan per device; and it features an innovative modular design that can quickly adapt to mainstream loom types such as water-jet, air-jet, and rapier looms, compatible with diverse fabrics including cotton, linen, silk, chemical fibers, and blends, reducing debugging time to within 15 minutes and significantly lowering labor costs.

"The deployment of this Leno device has increased the qualification rate of our high-end fabric weaving from 92% to 98.5%, raised production line speed by 15%, and reduced comprehensive production costs by 8%," said the production director of a large textile enterprise in Zhejiang that was among the first to trial the product. Currently, the product has obtained multiple national invention patents and passed ISO9001 quality system certification. In addition to the domestic market, it is also exported to textile industry hubs in Southeast Asia and Europe, receiving widespread recognition from overseas clients.

Industry experts point out that the mass production and implementation of the intelligent Leno device not only fills the technological gap in high-end textile machinery accessories domestically but also promotes the transformation of the textile industry from "scale expansion" to "quality and efficiency." In the future, with the deep integration of digital and intelligent technologies in the textile machinery field, more efficient, energy-saving, and intelligent core accessories will emerge, injecting new momentum into the green and low-carbon development of the global textile industry.

Please visit product page for more information

-

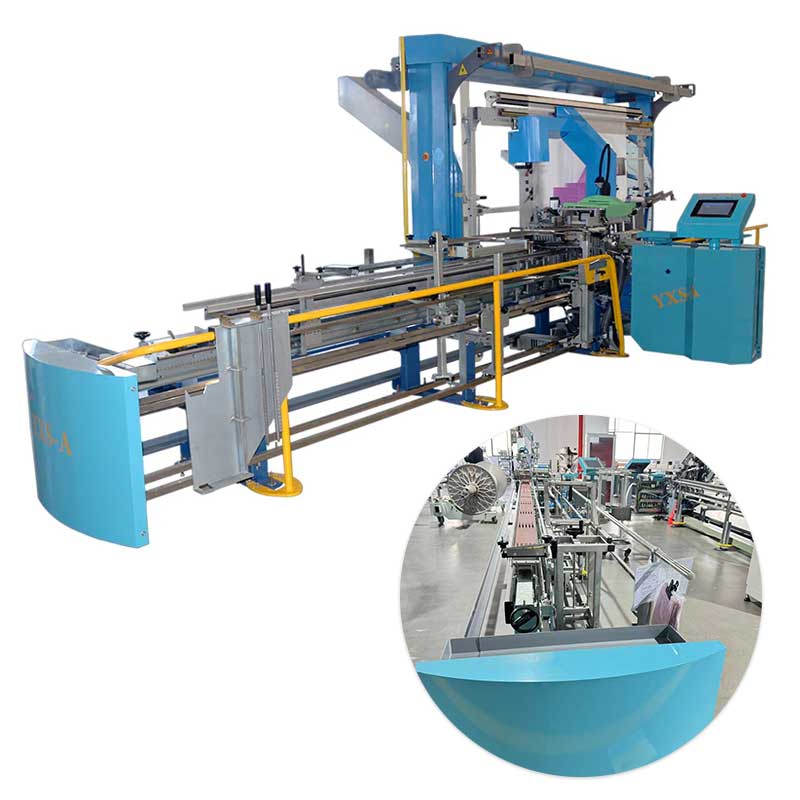

Leno Device 330 For Weaving Extile Machinery

Product descriptions from the supplier Overview: Our company specializes in the production and sales of various textile machinery accessories. Mainly engaged in high speed rapier loom rapier head, rapier belt, sword wheel, guide hook, guide rail, weft scissors, water jet and air jet looms accessories. A large number of our products are sold to all over the world, complete models, quality is guaranteed, sincerely welcome you to consult and discuss cooperation !

More

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts

-

- The journey of deepening the textile accessories business of Changzhou Yongxusheng Technology Co., Ltd.

- Innovation Drives Textile Efficiency Revolution: New Generation Intelligent Leno device Leads Industry Upgrade

- Fully Automatic Drawing Machine Lead the Textile Industry into a New Era of Efficiency and Precision

- Automatic Drawing-in Technology Achieves Substantial Breakthrough, Helping Textile Enterprises Overcome "Labor Shortage" and "Quality Challenges"