Product recommendation

Flat steel Heald wires, heddle are used to lead the warp yarns to move in lifting motion, forming a weaving shed for weft yarns to be brought in.

Our offered heald wire is well-manufactured by using of superior quality stainless steel. The edges of our steel heddles are well polished and available with thread eye for impeccable weaving of fine and low twist wrap yarn. Moreover, our range of heald wires is suitable for all types of mechanical and electrical wrap stop motions.

Also, we check these products upon various parameters so as to avoid any trouble from customer side. Different specifications weaving healds are available to meet the clients' specific needs.

Specification of closed type flat steel healds wire , heddle wire

Type | Cross Section | Length | |

Kind | Shape | Width*Thickness(mm) | Distance between end loops |

Closed type | Simplex (S) | 2.20*0.30 |

280 330 300 380 302 420

|

2.34*0.35 | |||

Douplex(D) | 2.50*0.35 | ||

2.60*0.40 | |||

Unilateral Douplex (P) | 2.80*0.40 | ||

2.50*0.30 | |||

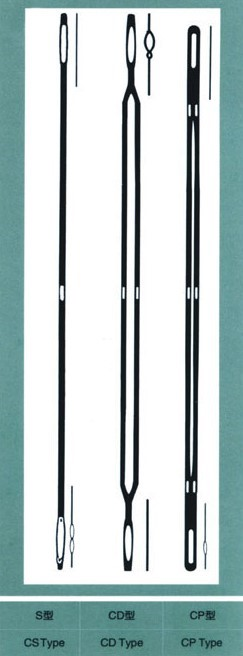

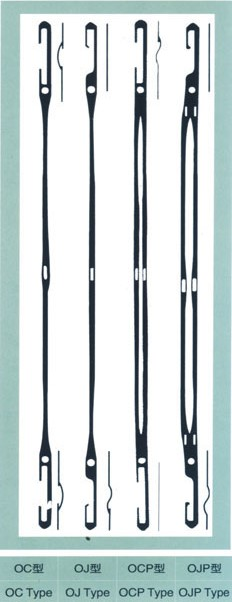

Schematic diagram of mail-eye for closed flat steel healds

Closed type flat steel healds

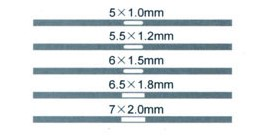

Specification of open type flat steel healds

Type | Cross Section | Length | |

Kind | Shape | Width*Thickness(mm) | Distance between end loops |

Oopentype | Simplex (J) Douplex(JP) Simplex (C) Douplex (CP) | 5.50*0.23 |

280 382 302 407 331 432 356

|

5.50*0.25 | |||

5.50*0.30 | |||

5.50*0.38 | |||

5.50*0.40 | |||

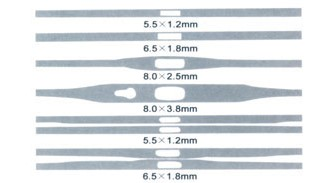

Type ofthread eye | Type of end loop | ||||

Position of the thread eye | Code | Size | Code | Upper loop | Lower loop |

U above center C in the center | 2 | 5.5*1.2 |

-5 -6 -7

| ||

4 | 6.5*1.8 | ||||

5 | 8.0*2.5 | ||||

6 | 8.0*3.8 | ||||

Schematic diagram of mail-eye for open flat steel healds

Open type flat steel healds

Please visit product page for more information

-

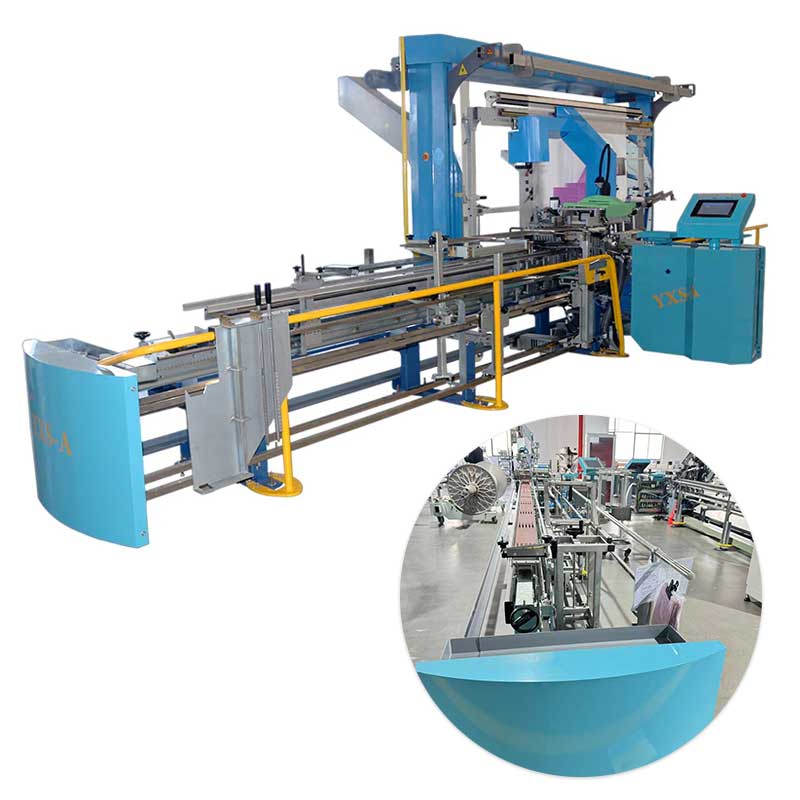

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts

-

- The journey of deepening the textile accessories business of Changzhou Yongxusheng Technology Co., Ltd.

- Innovation Drives Textile Efficiency Revolution: New Generation Intelligent Leno device Leads Industry Upgrade

- Fully Automatic Drawing Machine Lead the Textile Industry into a New Era of Efficiency and Precision

- Automatic Drawing-in Technology Achieves Substantial Breakthrough, Helping Textile Enterprises Overcome "Labor Shortage" and "Quality Challenges"