Product recommendation

It is type of steel wire with an eye in the Centre or in another words, it is a similar device through which a warp yarn is threaded, which is used to lead the warp yarns to move in lifting motion. Generally, these heald wires are developed for wire weaving machines.

Our Kataria, manufactured range of heald wire enables the yarn to be raised or lowered during weaving to create a shed. Our offered heald wire is well-manufactured by using of superior quality stainless steel. Our highly qualified and determined professionals made variety of heald wires with different sizes and types of loops, eye holes, strip width, thickness and plating.

At our manufacturing unit, offered range of heald wires are made in adherence that actually matches the international quality standards. Also, our all products are developed under the strict control and supervision of our industry experts. Apart from this, our team and infrastructure facilities enable us to execute the whole processing within the prescribed time frame.

Our company is striving hard to provide the top grade heard wires to their domestic and international clients that are sourced from genuine and trustworthy vendors of the industry. Additionally, our qualitative range of heald wires are widely demanded and appreciated for their smooth performance, sturdiness, durable finish, corrosion resistance, easier installation and reliability. Fully scientifically controlled in house electroplating is one of the best feature of our manufactured product that gives maximum rust protection life.

Specification if Flat Heald Wires

Length | 220 MM To 382 MM |

Width | 5.5 MM / 6 MM / 6.64 MM / 7.2 MM |

Thickness | 0.2 MM To 1 MM |

Type | C, J, O, Simplex, Duplex |

Eyelet Size | 5.5×1.2, 6.5×1.8, 6.5×2.5, 7.8×3.8, 8×3.8, 8×2. |

Eyelet Position | In centre, 5 MM above centre |

Moc | Stainless Steel, High Carbon Spring Steel Strip |

Plating | Nickel, Zinc |

Types of Heald Wires We Offers

· Riderless Stainless Steel Wire Healds

Please visit product page for more information

-

280 Type O Double Column Steel Heald Wires For Weaving woven Machine

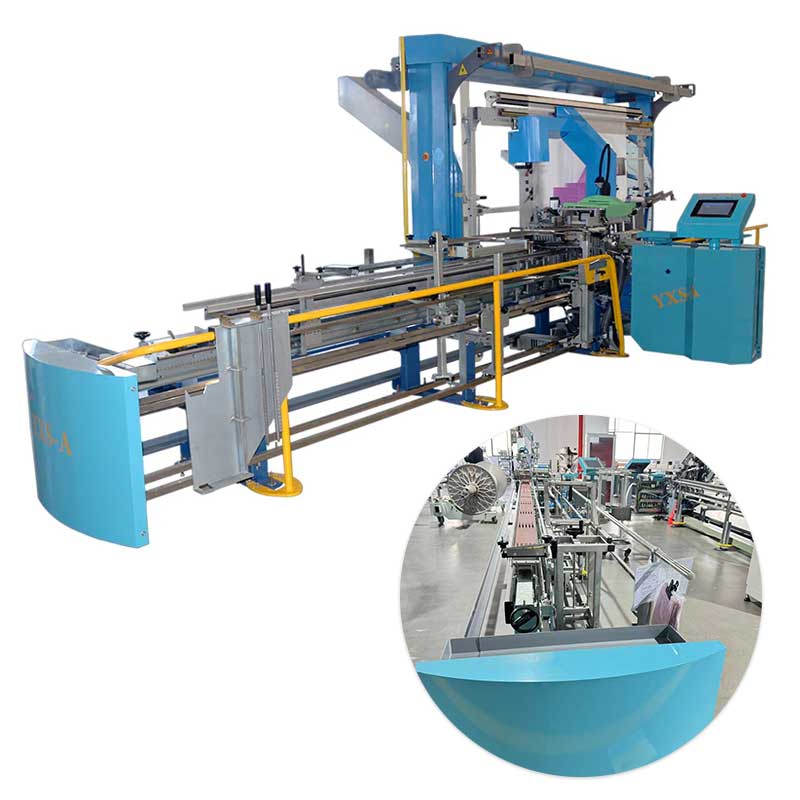

Since its establishment in 2013, Yongxusheng Textile Factory has gone through more than ten years. With deep technical accumulation and rich industry experience, we continue to innovate, and successfully developed automatic threading machine and various textile machinery accessories. Our technical team consists of more than 20 professional mechanical engineers, who constantly inject innovation into the company. Through continuous technological innovation, Yong Xusheng has become a leader in the industry and provides customers with efficient and reliable textile solutions. Needle Loom Healds,Yarn Healds 280 Type O Double Column Steel Heald Wires

More

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts

-

- The journey of deepening the textile accessories business of Changzhou Yongxusheng Technology Co., Ltd.

- Innovation Drives Textile Efficiency Revolution: New Generation Intelligent Leno device Leads Industry Upgrade

- Fully Automatic Drawing Machine Lead the Textile Industry into a New Era of Efficiency and Precision

- Automatic Drawing-in Technology Achieves Substantial Breakthrough, Helping Textile Enterprises Overcome "Labor Shortage" and "Quality Challenges"