The basic structure of the fully automatic warp drawing machine

2024-06-05

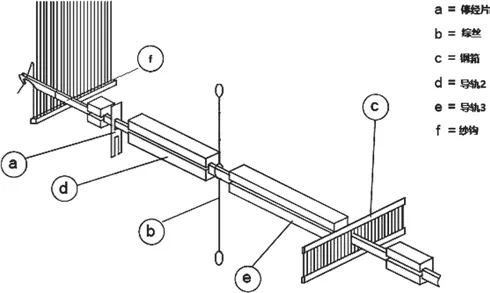

Machine drawing in is to use a machine to thread the yarn of the warp beam through the dropper, heald and reed according to the process requirements, which is a preparatory work before weaving. As early as the 1950s, people in Europe, where the industry first started to develop, had begun to develop machines for drawing in warps. It has been more than 60 years since the first drawing in machine was put into production. The basic structure of the currently used drawing in machine is shown in Figure 1.

The warp drawing process is controlled by a perforated card. The machine is equipped with a mobile creel for drawing the warp on the warp beam. The fastest drawing speed is designed to be 180 yarns/min. It was basically used in cotton textile mills until it was basically discontinued in 1991. There are about two such machines in China, which are old equipment introduced by foreign-funded textile mills.

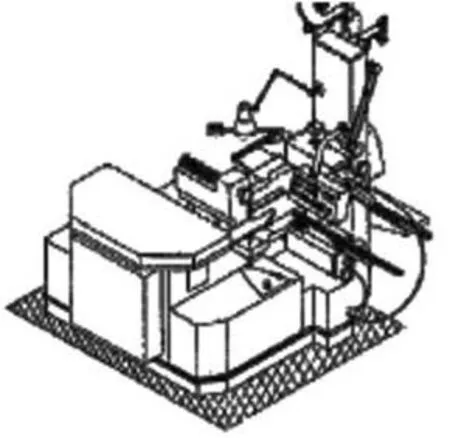

According to the needs of warp drawing, the machine is divided into two parts: the creel car and the head. The warp beam is carried by the warp beam car and connected to the creel car, and then the yarn sheet ready for drawing is set on the creel. The head defines four major functional modules, namely the yarn module, heald module, reed module and dropper module.