Textile machine operation threading and cloth dropping operation process

2024-06-06

Warp creel threading operation

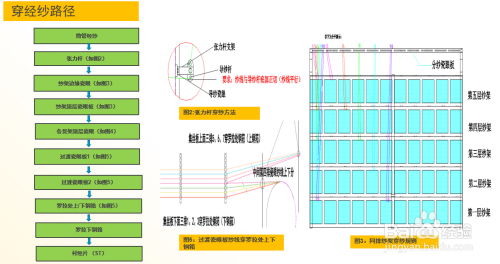

Rules for inserting porcelain eye plates on the same row of creels

Note: 1, 3, 5, 7, 9 are the bobbins in the front row of the creel;

2, 4, 6, 8, 10 are the bobbins in the back row of the creel

The warp creel threading starts from the head of the warp knitting machine, and the space is at the tail of the machine;

That is: the front bobbin of the 5th layer of the creel is placed on the 1st porcelain eye of the machine head;

the back bobbin of the 5th layer of the creel is placed on the 2nd porcelain eye of the machine head;

......

the front bobbin of the 1st layer of the creel is placed on the 9th porcelain eye of the machine head;

the back bobbin of the 1st layer of the creel is placed on the 10th porcelain eye of the machine head

arp knitting machine material change weft threading operation

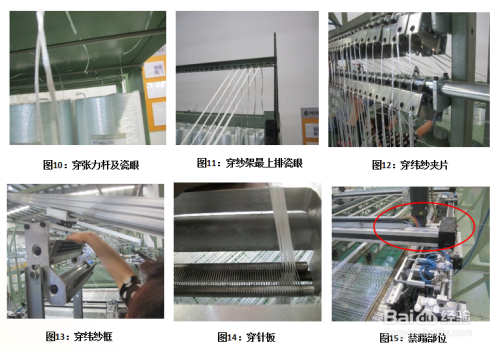

a. The weft yarn passes over the rack tension rod and through the porcelain eyelets on the edge of the rack, as shown in Figure 10.

b. The weft yarn passes through the top row of porcelain eyelets on the rack, as shown in Figure 11.

c. The weft yarn passes through the weft yarn clamp, as shown in Figure 12.

d. The weft yarn passes through the weft yarn frame, as shown in Figure 13.

e. The weft yarn passes through the needle plate, as shown in Figure 14.