Technological Upgrade of "Drop Wire" - Core Component of Textile Machinery, Boosting the Industry's Intelligent Transformation.

2025-08-08

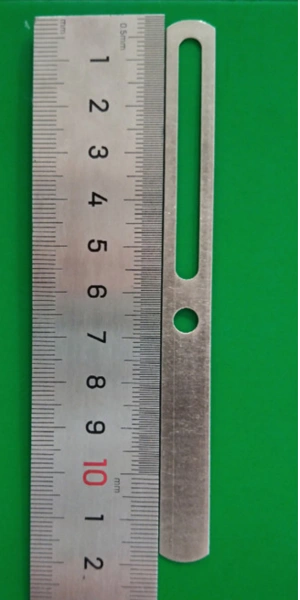

Recently, technological innovations in "Drop Wire" – a key component of textile machinery – have become the focus of the industry. As the core part of the loom's yarn breakage detection system, the drop wire accurately senses changes in warp tension to achieve immediate shutdown when a yarn breaks. Its performance directly affects weaving efficiency and product quality. Traditional drop wires suffer from issues such as insufficient sensitivity and rapid wear. The newly developed third-generation product adopts high-strength alloy materials and precision stamping technology, shortening the response time to 0.02 seconds and increasing the yarn breakage detection accuracy to 99.98%, while extending the service life by more than 3 times. A person in charge of a textile machinery manufacturer stated: "The upgraded drop wire has improved the overall equipment efficiency by 15%, reducing annual downtime losses for enterprises by nearly one million yuan." With the development of the textile industry towards intelligence and high speed, the technological iteration of precision components like drop wires has accelerated. Data shows that the global market size of textile machinery components exceeded 8 billion US dollars in 2023, with intelligent detection components growing at a rate of 22%. Industry experts point out that the performance optimization of drop wires will drive shuttle less looms towards "zero-defect production" and provide key support for cost reduction and efficiency improvement in the textile industry. Currently, the new drop wire has passed the EU CE certification and started mass supply to major domestic and foreign loom manufacturers. Technological innovation continues to inject new vitality into traditional textile equipment,and promote the environment better.