One Thread, Ten Thousand Ends: China’s Automatic Drawing-In Machine Reshapes Weaving Preparation

2025-08-07

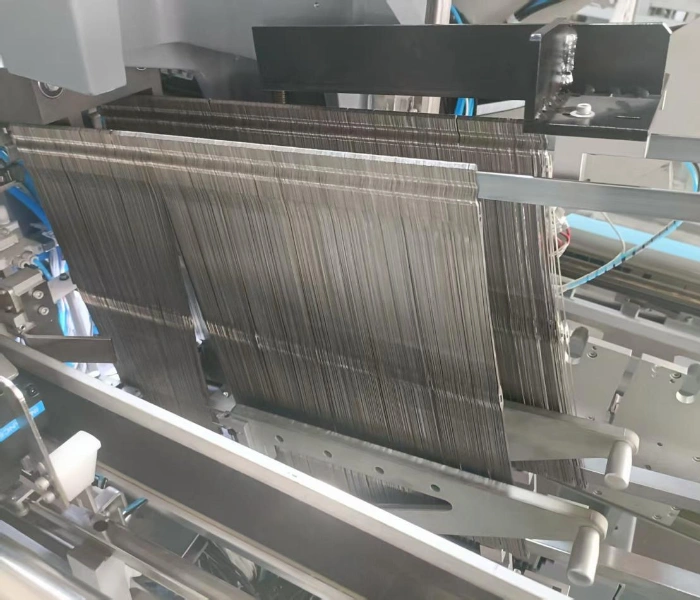

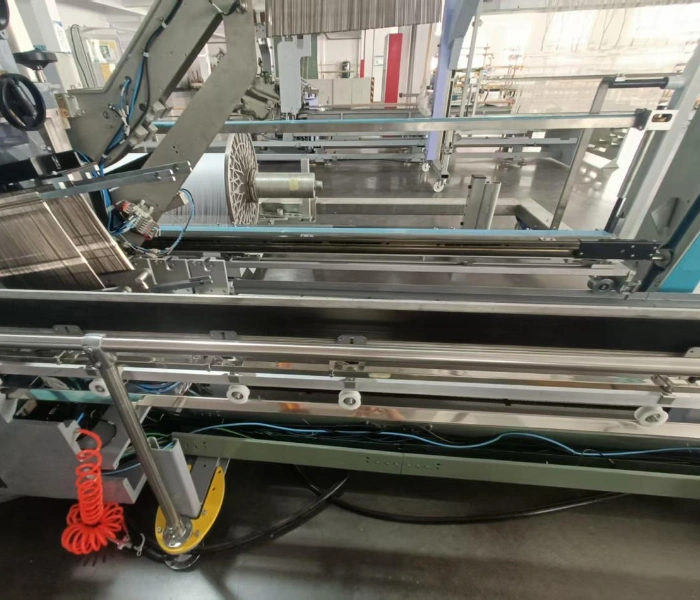

“One thread, ten thousand looms” is now a daily reality on the factory floor. The automatic drawing-in machine compresses what used to be seven labor-intensive hours into less than sixty minutes, fundamentally resetting the rhythm of weaving preparation. Once started, a servo motor separates each warp end under constant tension; vibratory feeders queue drop wires and healds in perfect order. Vacuum nozzles or mechanical needles then pull every yarn through heald eyes and reed wire dents in a single motion, while machine-vision cameras watch for double ends or mis-draws and instantly halt the cycle if anything is wrong. The entire process—separation, feeding, drawing, inspection and frame delivery—forms a closed, five-step loop that runs without interruption.

Benefits are just as clear-cut: steady speeds of 160–300 ends per minute allow one unit to replace seven to eight skilled workers; AI vision coupled with closed-loop tension control cuts fabric defect rates by 60 % and shortens payback to under three years; style change-overs are now a matter of loading a new program, cutting set-up time from half a day to ten minutes—exactly what small-lot, quick-response markets demand.

Domestic models already cover reed widths from 2.3 m to 4 m and handle cotton, linen, filament, staple and colored yarns, coping with complex weaves using up to twenty-eight heald frames. In 2024, Chinese-made automatic drawing-in machines achieved a domestic penetration rate of 35 % and were exported to 23 countries, including Uzbekistan and Vietnam, with annual growth exceeding 120 %. With “Active Warp Control 2.0” scheduled for release in 2025, drawing-in speeds are expected to reach 200 ends per minute, bringing the weaving mill another step closer to truly operator-free preparation.