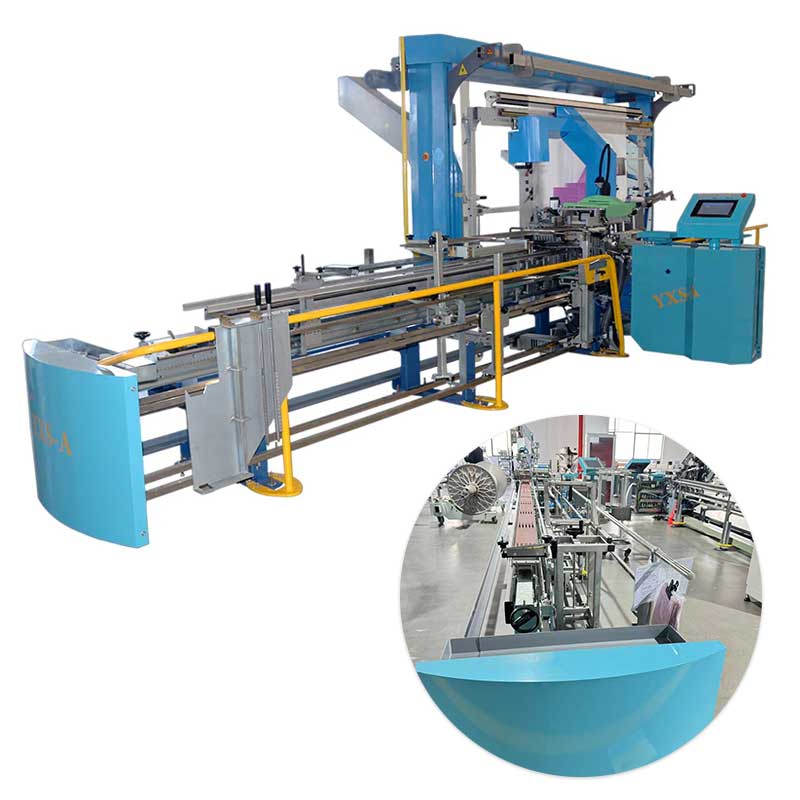

Product recommendation

Warping is a crucial step in textile processing, involving dyeing, finishing, printing, and other aspects. To ensure accuracy and efficiency in warping, using calculation formulas is essential. This article introduces several common warping calculation formulas and provides a step-by-step guide to the warping process.

Total number of roots calculation

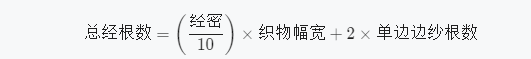

Basic formula

Parameter Description:

Warp Density: Number of warp yarns per 10 cm of fabric (unit: yarns/10cm)

Fabric Width: Width of the finished fabric (unit: cm)

Side Yarn Count: Number of warp yarns along both edges of the fabric; usually added symmetrically.

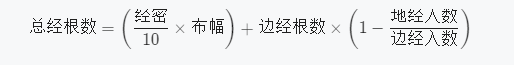

Correction Formula (considering reed weaving differences)

Corrected scenario: When the weaving methods for the ground warp and edge warp are different (e.g., 2 threads per reed for the ground warp, 4 threads per reed for the edge warp)

Note: If in inches, a rough calculation can be used: Total warp threads = Warp density * Fabric width

For example: Rough calculation of total warp threads: 130 * 63 = 8190 threads

Please visit product page for more information

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts

-

- Warping calculation formula for textile weaving

- Textile weaving knowledge: weaving heddles

- Value-Driven and Resilient Reshaping: Technological Breakthroughs in the New Cycle of Global Apparel Trade

- Technological Innovation of "Rapier Heald" – Core Component of Textile Machinery – Leads the New Future of Weaving