Textile weaving knowledge: weaving heddles

2025-12-12

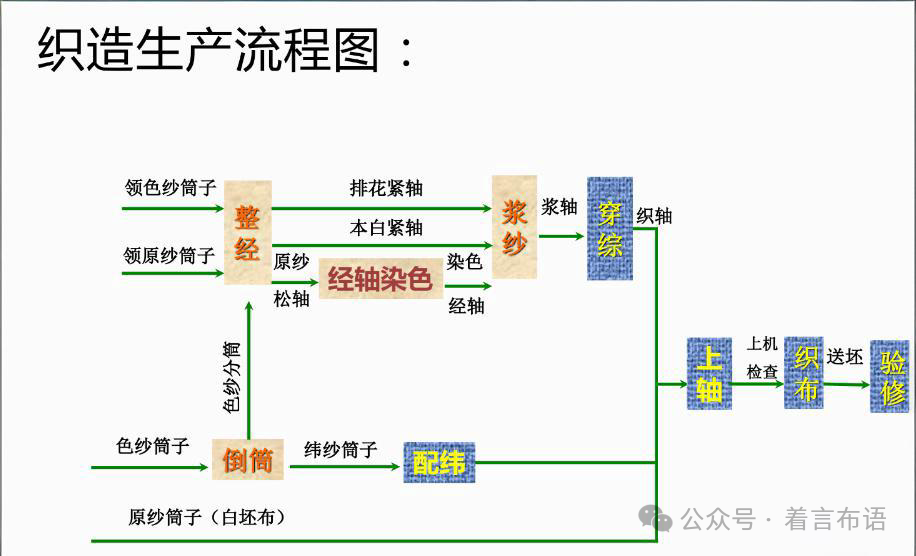

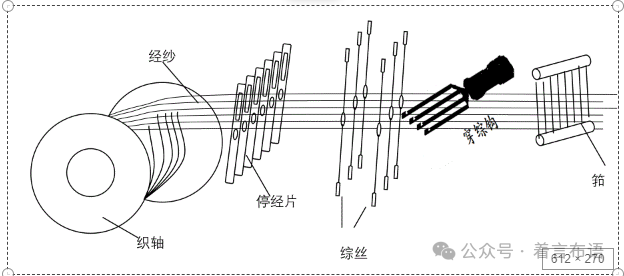

The warp threading process is a crucial step in the weaving preparation, occurring after the warp yarns are installed on the warp beam and before weaving begins on the loom. Its main task is to guide the warp yarns, one by one, through components such as the stop warp pads, heddles, and reed, according to the fabric structure design. The stop warp pads control the starting and stopping positions of the warp yarns, the heddles support and guide the warp yarns, and the reed serves as the basis for the interlacing of the warp and weft yarns. The accuracy of the warp threading directly affects the formation of the fabric structure, the presentation of the pattern, and the smooth progress of the weaving process.

Definition of heddle threading: This process involves passing each warp yarn through the stop bar, the heddle eye, and the reed teeth, preparing a length of warp yarn sufficient for the machine to reach the front.

Heddle threading methods: Manual operation or automatic operation with a heddle threading machine, automatically splicing warp threads.

Manual heddle threading steps:

1. Transfer the warp yarns from the weaving beam to the heddle threading frame and clamp them securely.

2. Thread the stop warp (if available, use an automatic stop warp threading device).

3. Thread the heddles according to the required sequence in the process design.

4. Insert the reed according to the insertion count.

Disadvantages: Prone to errors, high manual labor intensity, slow speed. Each person can thread approximately 1000 yarns per hour by hand, and it generally takes 2-3 days to complete one warp beam.

Automatic heddle threading steps:

1. According to the fabric process, the warp yarns are arranged and then separated using a slitting machine.

2. The warp yarns are loaded onto the automatic heddle threading machine's frame.

3. The heddles and stop warp pieces are loaded.

4. The arrangement of the heddles and stop warp pieces is entered into the computer.

5. Operation.

Advantages: High speed, low error rate, high output (approximately 100,000 warp yarns/day).

Automatic warp splicing steps:

1. Clamp and arrange the yarn on the weaving beam using the clamps of the automatic warp splicing machine.

2. Clamp and arrange the yarn on the weaving beam to be spliced using the clamps of the automatic warp splicing machine.

3. Place the yarn on the warp splicing machine frame and comb it with a metal comb until it is parallel.

4. Start the machine and begin splicing.

Advantages: High speed, high capacity, can be started directly, reduces the beam loading process. Disadvantages: Many restrictions, requiring specific reed numbers, heddle wire order, and total warp length for both varieties.

Main components of heddle making: heddle frame, reed, stop-warp piece.

1. Heald Frame: The heald frame consists of heald wires, a heald frame, and a heald rod.

2. Reed: The reed determines the warp density of the fabric, directs the weft yarns towards the shed, and also serves as a guide for the shuttle as it passes through the shed. The density of the reed teeth is usually expressed in reed number, which is the number of reed teeth per 10cm. Imperial reed numbers are expressed as the number of reed teeth per two inches (1 inch = 2.54cm).

3. Stop Sheet: The stop sheet is a key component of the loom's stop device. Its function is to immediately stop the loom when a warp yarn breaks, thereby improving product quality and labor productivity. The allowable density of the stop sheet on the stop bar is related to the warp count. Higher yarn counts and finer diameters allow for a higher density and thinner stop sheets; lower yarn counts and coarser diameters require a lower density and thinner stop sheets. (There are two types of menopause pads: open and closed.)

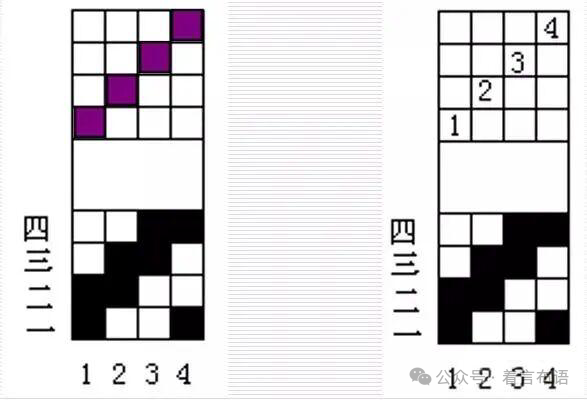

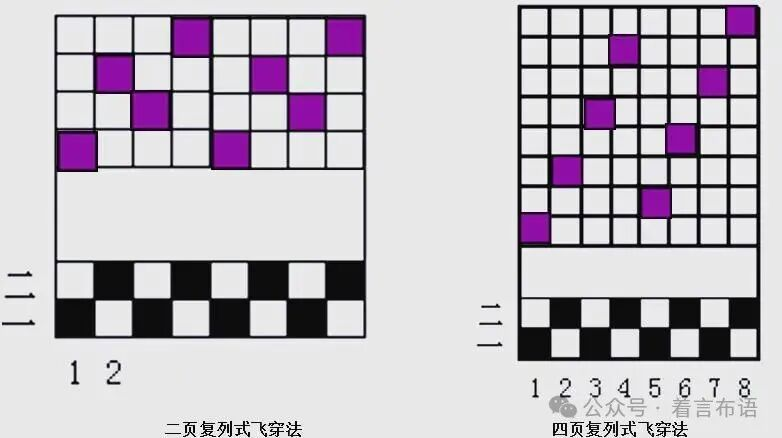

There are three ways to thread menopause pads: threading them in sequence (1, 2, 3, 4), threading them in a flying motion (1, 3, 2, 4), and threading them in overlapping patterns (1, 1, 2, 2, 3, 3, 4, 4).

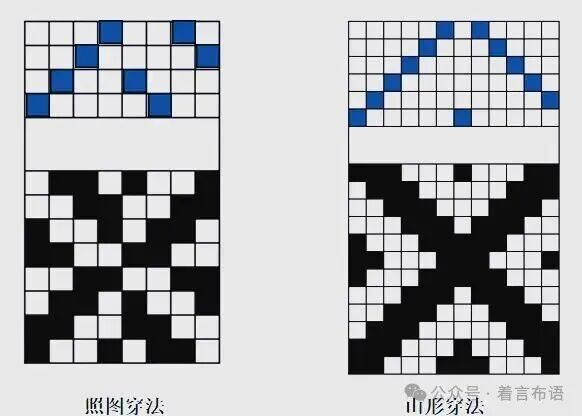

Commonly used heddle threading methods:

Forward threading method: Thread the heddle into each heddle frame in sequence according to the warp yarns. Suitable for simple weaves and small patterned fabrics. It is easy to operate but the heddle frame utilization rate is low.

Flying through method: The warp yarns skip through the heddle frame at intervals. This method is suitable for high-density fabrics and can reduce the load on the heddle frame.

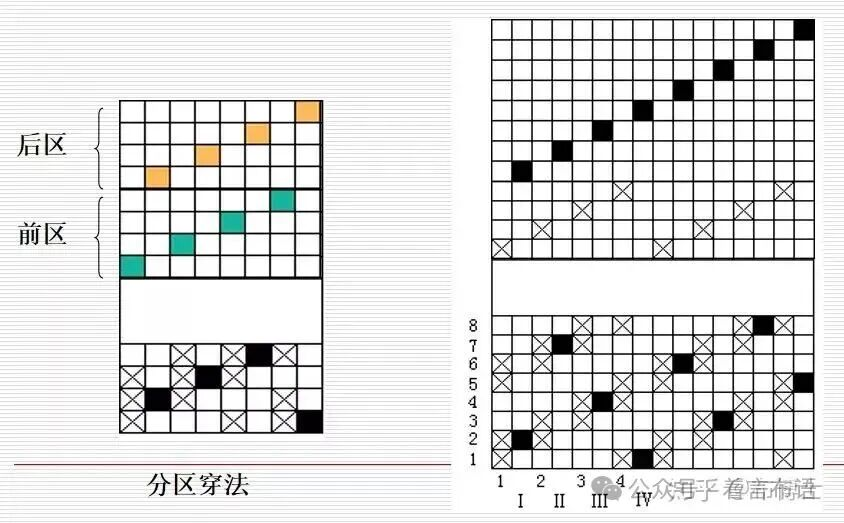

Sectional weaving method: When the fabric contains warp yarns of different structures or properties (such as ground weave and pattern), the heald frame should be divided into front and back sections, and the warp yarns that interweave frequently should be worn in the front section.

Following the pattern (saving heddle stitching): Warp yarns with the same rising and falling pattern are stitched into the same heddle frame, saving the number of heddle frames and suitable for complex patterns.