Product recommendation

Recently, within the vast industrial system of textile machinery, a key component called "rapier heald" is quietly triggering a new round of technological upgrading and industrial efficiency revolution. As the "heart" and "execution terminal" of rapier looms, even subtle improvements in its performance directly relate to fabric quality, production efficiency, and enterprises' core competitiveness.

Small Yet Critical: The "Precision Dancer" on the Loom

The rapier heald is the core executive component of the weft insertion system in rapier looms. Its responsibility is to accurately clamp, transmit, and hand over weft yarns during high-speed operation, completing the crucial step of warp-weft interweaving. This compact metal component, usually only the size of a palm with a sophisticated structure, endures hundreds of high-frequency impacts and friction per minute. The wear resistance of its material, structural stability, clamping precision, and surface finish directly determine whether the loom can efficiently produce flat, firm, and flawless fabrics, as well as the range of yarn types it can adapt to.

For a long time, the design and manufacturing technology of high-end rapier healds have been an important benchmark for measuring the level of textile equipment of a loom manufacturer and even a country. Bottlenecks in its performance often restrict the improvement of the overall machine speed, the reduction of energy consumption, and the breakthrough of fabric quality.

Technological Breakthroughs: From "Hard" Strength to "Intelligent" Perception

Currently, rapier heald technology is evolving along multiple dimensions:

1. Material and Process Upgrading: Adoption of new materials such as special alloys and ceramic composite coatings significantly improves the wear life of rapier healds and reduces damage to high-count and fragile yarns. The application of precision machining processes and laser surface treatment technology ensures that their geometric accuracy and consistency reach the micron level.

2. Structural Design Optimization: Through computational fluid dynamics analysis and finite element simulation, the shape, yarn guide grooves, and clamping mechanism of rapier healds are optimally designed to reduce air resistance, lower noise and vibration, and achieve smoother and gentler weft insertion. This is particularly suitable for the production of high-speed looms and high-grade fabrics.

3. Intelligent Integration: Some cutting-edge designs have begun to integrate micro-sensors to real-time monitor the status of rapier healds, yarn tension, and even wear precursors. This provides a data foundation for predictive maintenance and adaptive adjustment of process parameters, advancing weaving toward greater intelligence and digitalization.

Industrial Impact: Efficiency, Quality, and Green Weaving

Every advancement in rapier heald technology is effectively transformed into benefits for downstream textile enterprises:

- Improved Efficiency and Wider Adaptability: More durable and reliable rapier healds reduce downtime for replacement, higher operating speeds increase productivity, and better handling of differentiated raw materials enhances production flexibility.

- Guaranteed Excellent Quality: Precise weft insertion significantly reduces defects such as weft breakage, fabric bars, and floaters, laying a solid foundation for the production of high-grade garment fabrics, home decorative fabrics, and industrial textiles.

- Promotion of Energy Conservation and Consumption Reduction: Optimized design reduces the operating load of looms, directly lowering energy consumption and aligning with the global trend of green and sustainable development in manufacturing.

Future Outlook: The "Foundation-Strengthening" Path of Core Components

Industry experts point out that although small, the rapier heald is a typical representative of the "foundation-strengthening project" in the textile equipment industrial chain. Its technological breakthrough relies on the interdisciplinary integration of materials science, precision manufacturing, simulation design, and other fields. In the future, with the continuous emergence of new materials, the application of new processes such as additive manufacturing, and deeper mechatronics and IoT integration, rapier healds will continue to evolve toward longer service life, higher intelligence, and greater specialization. They will become an indispensable "key piece" driving the textile industry toward high-endization, intelligence, and greenization.

It is foreseeable that this "precision heart" shuttling back and forth in looms will continue to beat with a steady rhythm, pulsating the more efficient, higher-quality, and more innovative development pulse of China's and even the global textile industry.

Please visit product page for more information

-

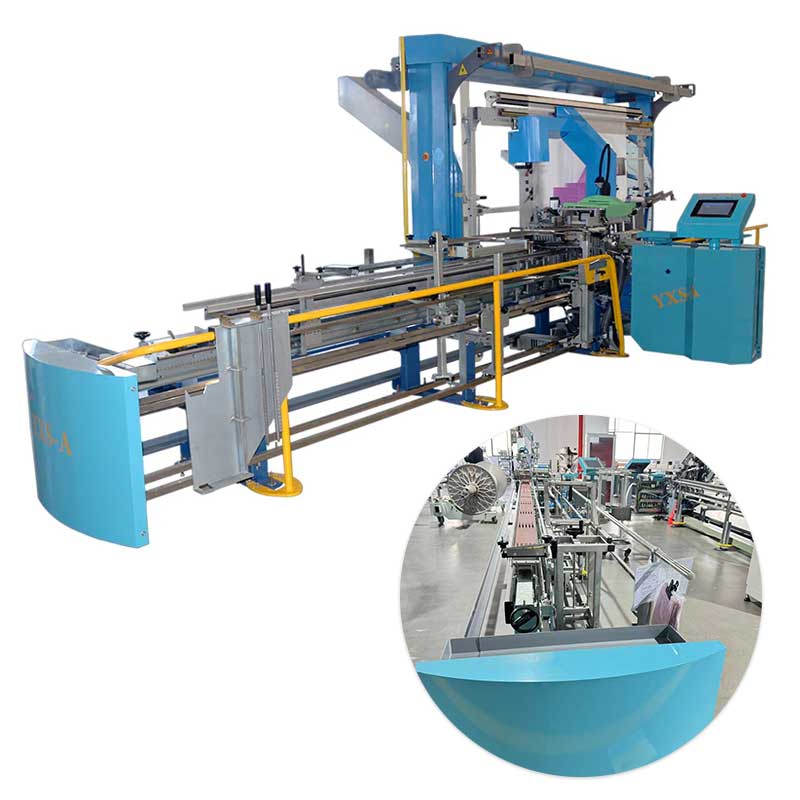

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts

-

- Textile weaving knowledge: weaving heddles

- Value-Driven and Resilient Reshaping: Technological Breakthroughs in the New Cycle of Global Apparel Trade

- Technological Innovation of "Rapier Heald" – Core Component of Textile Machinery – Leads the New Future of Weaving

- The journey of deepening the textile accessories business of Changzhou Yongxusheng Technology Co., Ltd.