Product recommendation

Amid the ongoing wave of intelligence and automation in the global textile industry, an innovation in a key preliminary process is quietly revolutionizing a traditional production model centuries old. As one of the most technically challenging and visually dependent steps in textile preparation, the warping operation has met its revolutionary force—the fully automatic warping machine. This cutting-edge equipment, integrating machine vision, artificial intelligence, and precision mechanical drive technologies, is unlocking a new chapter of cost reduction, efficiency improvement, and quality upgrade for global textile enterprises with its outstanding performance.

Moving Beyond 'Needlework': The Bottlenecks and Challenges of Traditional Warping

Warping is the precise process of passing thousands, even tens of thousands, of warp yarns from a beam sequentially through drop wires, heddles, and a reed according to technical design requirements. For a long time, this process heavily relied on the eyesight, concentration, and manual dexterity of skilled workers. It was not only labor-intensive and inefficient but also prone to mis-threading and missed ends due to fatigue, directly impacting the smooth progression of subsequent weaving and the quality of the final fabric. Faced with the widespread challenges of skilled labor shortages and rising costs in the global textile sector, traditional warping has become a significant bottleneck constraining the efficiency and flexible production of the entire industrial chain.

Technological Breakthrough: How automatic drawing machine Reshape the Production Flow

The emergence of fully automatic drawing machine perfectly addresses these pain points. Their core working principles are:

1. High-Precision Machine Vision System: High-resolution industrial cameras equipped on the machine act like 'intelligent eyes,' rapidly and accurately identifying and locating the position of each individual warp yarn, reliably capturing them regardless of color or thickness.

2. AI Analysis and Guidance: Algorithms based on deep learning process visual information in real-time, precisely charting the threading path, and intelligently adapting to various complex yarn arrangements and process requirements.

3. Precision Mechanical Actuator: Guided by the AI, a precise needle insertion mechanism performs a series of actions—grabbing, separating, guiding, and threading—with stability and speed far surpassing human capability, achieving a fully unmanned operation process.

Tangible Benefits: Delivering Multi-Dimensional Value Enhancement for Enterprises

The widespread application of automatic drawing machine brings immediate and lasting comprehensive benefits to textile companies:

· Ultimate Efficiency, Multiplied Capacity: Compared to the manual speed of threading dozens of ends per minute,automatic drawing machine can work consistently and stably at speeds of hundreds of ends per minute or even higher, increasing efficiency several times over, significantly reducing loom set-up waiting time, and accelerating order turnover.

Please visit product page for more information

-

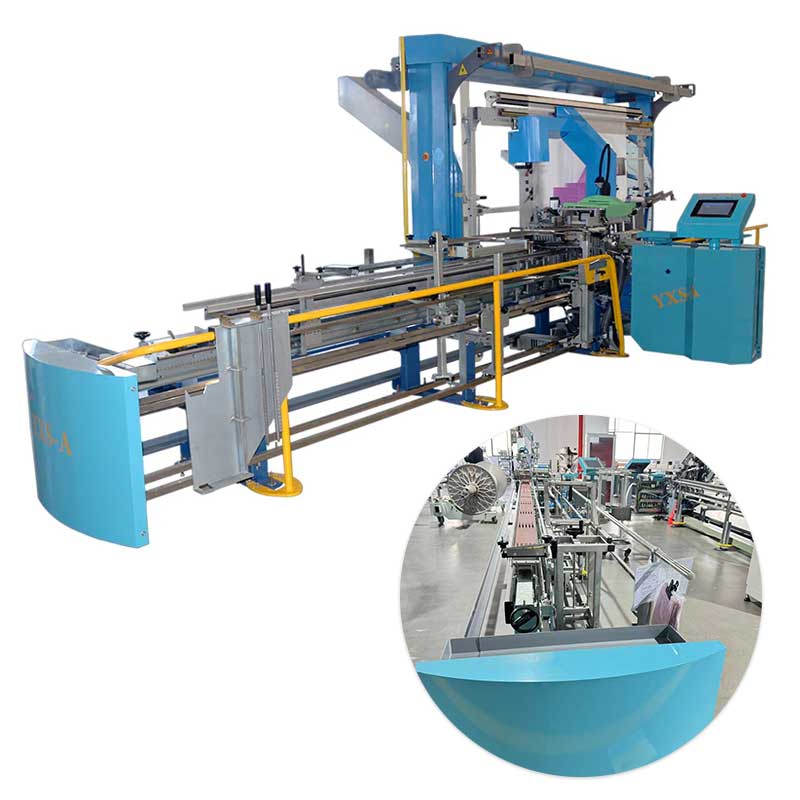

Textile Industry Machinery Automatic Threading Machine

Yongxusheng automatic drawing-in machine has an electronic double warp detection device, which can detect double yarns without twisting and automatically stop, which can improve fabric quality. Reducing the double warp reduces the generation of warp yarn wrong reed situation and improves the benefit of the loom.

More

-

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- Textile factory's automatic threading machines and other textile machinery accessories have been widely used in many markets at home and abroad.

- 280 Type C Simplex Column Steel Healds wires For Automatic Drawing-In Machine

- Heddle And Open Drop Wires 165*11*0.3 For Weaving Machine Spare Parts