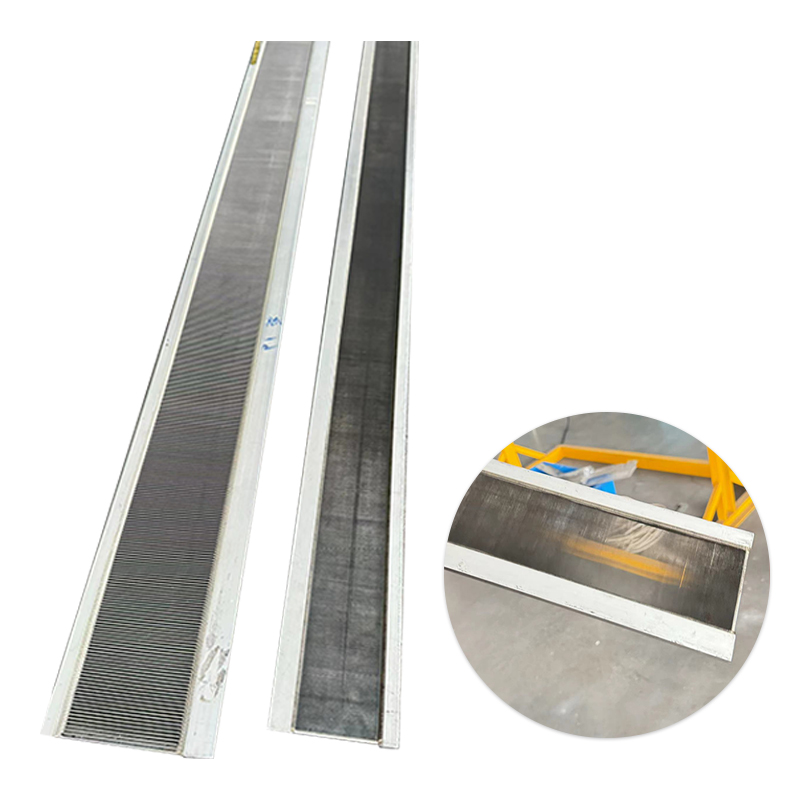

Shock Pad For Automatic Drawing-in Machine

Shock pads, also known as damping pads or cushions, are essential components in textile machinery that possess distinct characteristics and advantages in the weaving process. Shock pads are used in loom frames to absorb and dampen vibrations, impacts, and noise generated during machine operation. They offer several key features and benefits.

- YXS

- CHINA

- Ready to ship

- 1000000pcs per month

Details

Shock pads, also known as damping pads or cushions, are essential components in textile machinery that possess distinct characteristics and advantages in the weaving process. Shock pads are used in loom frames to absorb and dampen vibrations, impacts, and noise generated during machine operation. They offer several key features and benefits.

Firstly, shock pads are designed to provide effective vibration and impact absorption. They are made from resilient materials such as rubber or elastomers that can absorb and dissipate energy, reducing the transmission of vibrations through the loom frame. This feature helps to minimize machine vibration, enhance stability, and improve the overall performance and lifespan of the textile machinery.

Secondly, shock pads exhibit excellent noise reduction properties. They can effectively dampen the noise generated by the mechanical components of the weaving machine, creating a quieter and more comfortable working environment. The noise reduction provided by shock pads contributes to operator comfort, reduces noise pollution, and improves overall workplace conditions.

Moreover, shock pads are typically easy to install and replace. They come in various sizes and configurations to fit different loom frames, and their installation does not require complex procedures. When it comes to replacement, worn or damaged shock pads can be easily swapped out, minimizing machine downtime and maintenance costs.

Additionally, shock pads contribute to the protection of other machine components. By absorbing shocks and vibrations, they help to prevent excessive wear and tear on critical parts of the textile machinery. This protection extends the lifespan of various components, reduces the risk of breakdowns, and enhances the overall reliability of the equipment.

In summary, shock pads possess features such as vibration and impact absorption, noise reduction, ease of installation and replacement, and component protection. Their advantages include improved machine stability, reduced noise levels, ease of maintenance, and enhanced equipment durability in the textile industry.