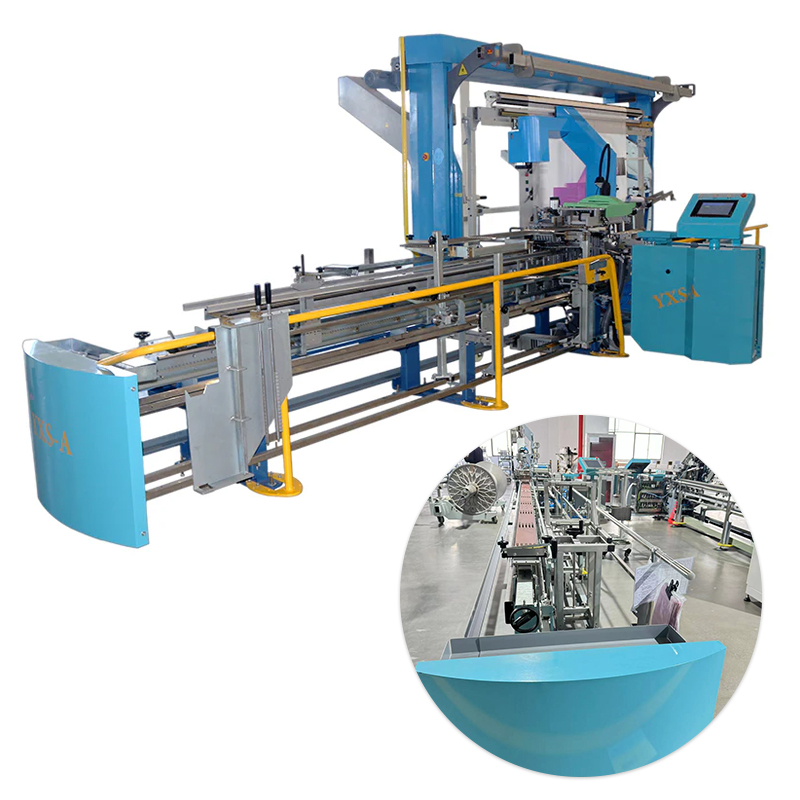

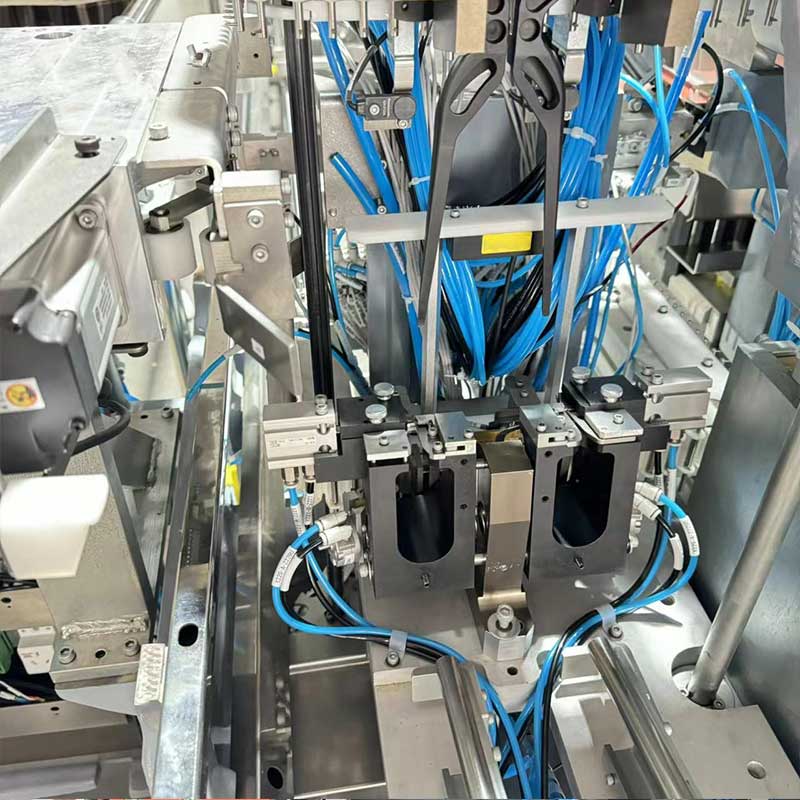

Automatic Drawing-in Textile Waving Machine

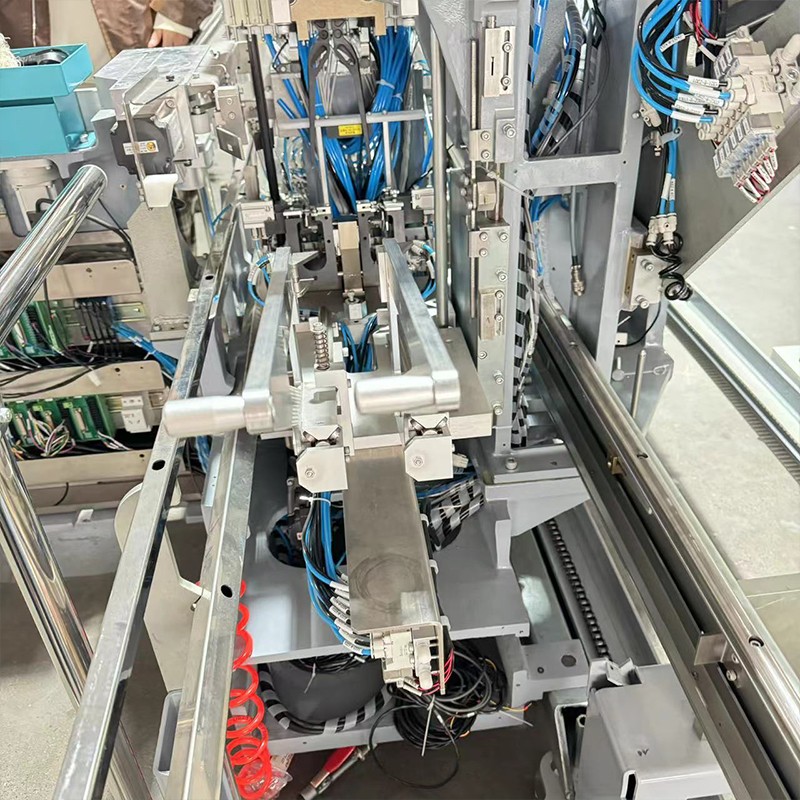

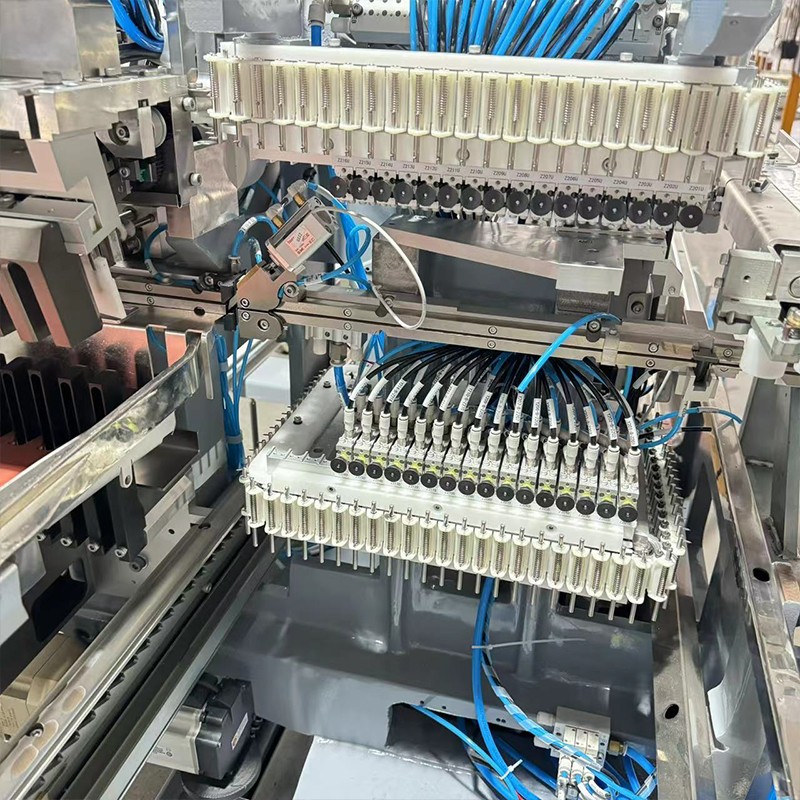

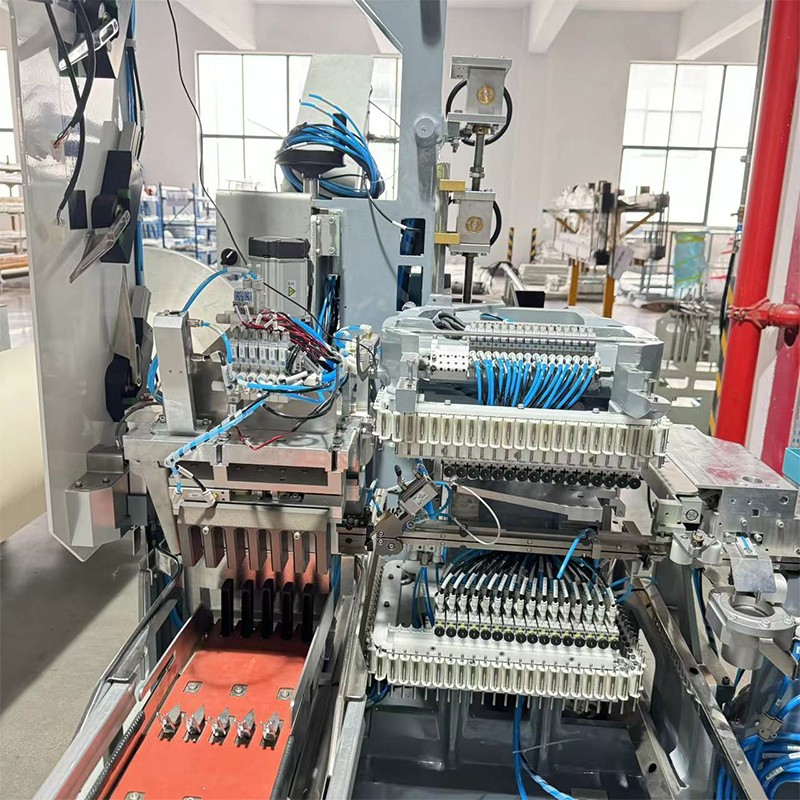

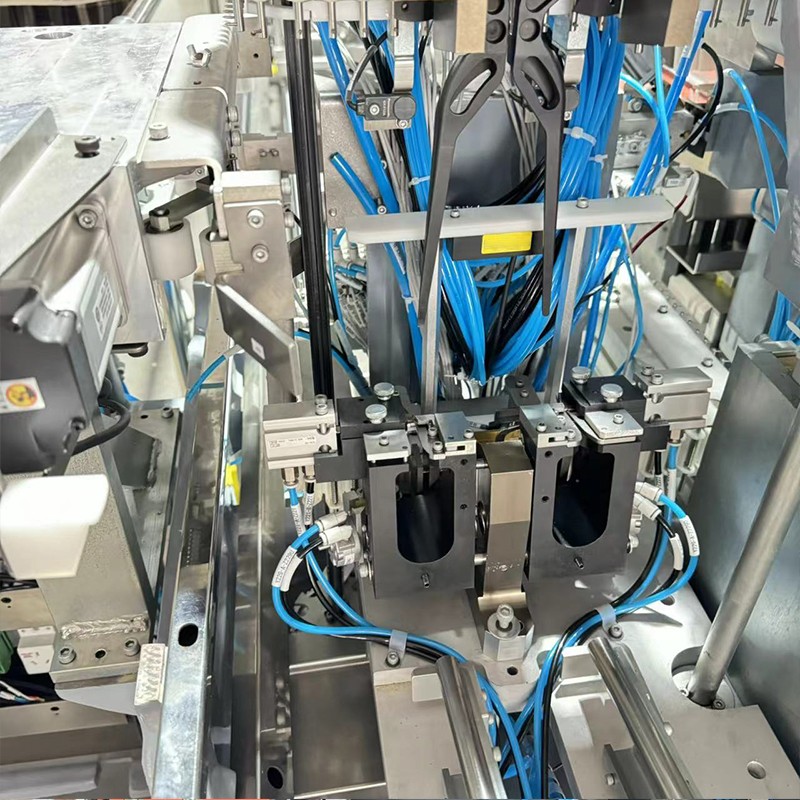

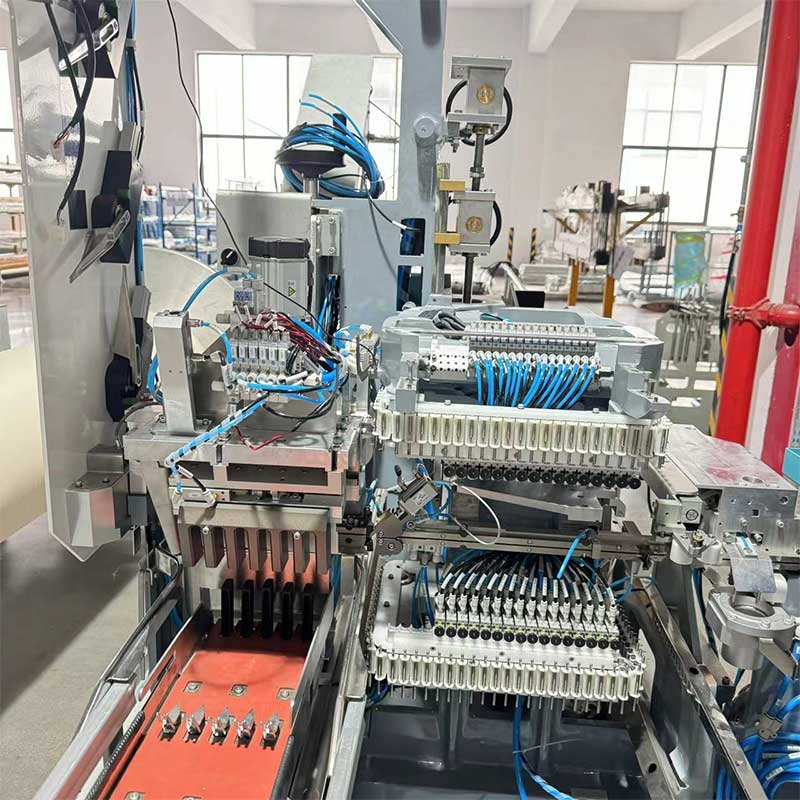

automatic drawing-in machine is equipped with electronic double detection device, that can automatically stop the machine once double warp yarns are detected. The use of drawing-in machine will effectively improve fabric quality, reduce drawing-in error and inrease weaving efficiency. The machine are manufactured in a modular design. Each machine is designed as per specific need of customer, more configuration can be added in future if needed. In one single process the drawin-in mechanism will thread through the drop wire, heddle wire and reed. The machine is applicable to almost all types drop wire, heddle wire and reed, including flat and profile reed. Textile Waving Machine

- Yongxusheng

- China-jiangsu

- To be negotiated

- 10000

Details

Model: YXS-A/M/L

Product Highlights

| Standard Configuration | Maximum beam width | 230cm/400cm |

| Creel trolley with lifting device | Yes | |

| A warp yarn layer leasing | Yes | |

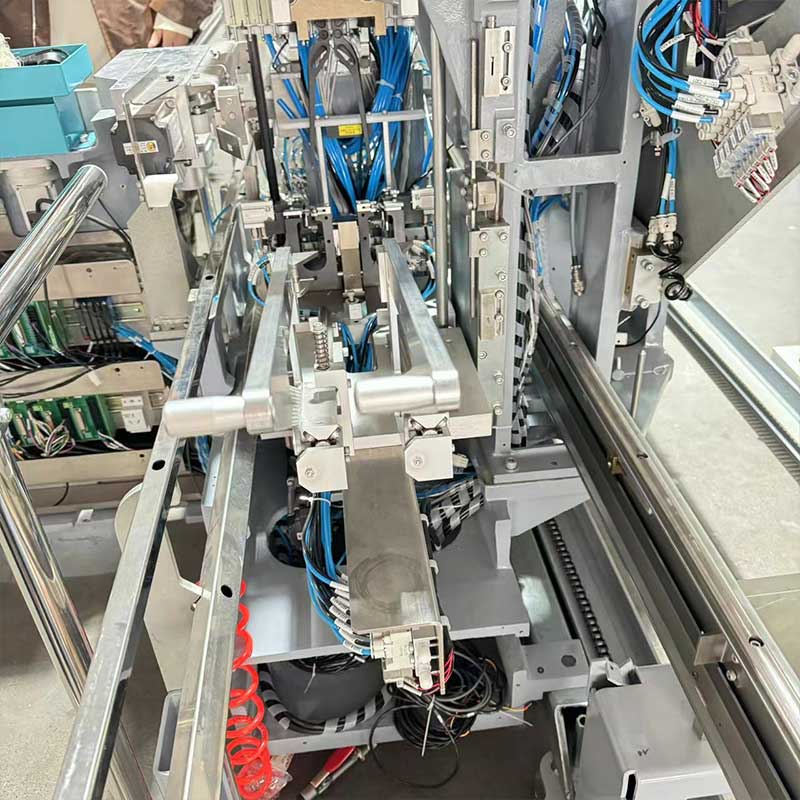

| Heddle wire module with two guide rail | Yes | |

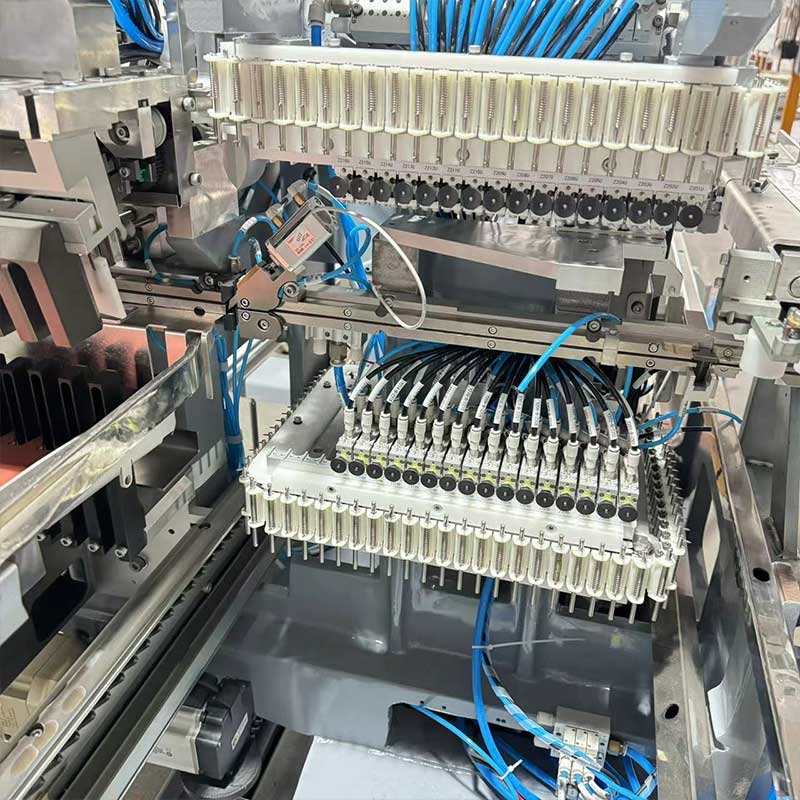

| Maximum number of heald frame (J/C type heddle) | 20 | |

| Maximum number of heald frame (O type heddle) | 16 | |

| Reed module | Yes | |

| Number of warp stop bar in warp stop module | 6 or 8 | |

| Double yarn detection | Yes | |

| Drawing-in | Maximum speed | 140picks/min |

| Applicable Yarn | Cotton yarn and blended yarn(carded and combed yarn) | Yes |

| Wool (carded and combed yarn) | Yes | |

| Silk, single filament and multiple filaments | Yes | |

| Flat wire up to 4.5 mm wide, slub yarn and boucle | Yes | |

| Special yarn | Yes | |

| Count | 20-100 | |

| Beam | The maximum nominal width | 230cm/400cm |

| Maximum beam diameter | 120cm | |

| One warp yarn layer with lease | Yes | |

| Heddle | Length of the heddle wire | 260-382mm |

| Thickness of the heddle wire | 0.25-0.38mm | |

| Healdloop | J/C/O | |

| Heald eye | Minimum 1.28x5.5mm | |

| Reed | Reed width | 230cm/400cm |

| Reed density (standard) | 20-350 teeth/decimetre | |

| Reed density (fine) | 351-500 teeth/decimetre | |

| Dent height | 40-100mm | |

| Reed height | 80-150mm | |

| Dent depth | Diameter16mm | |

| Reed type | The flat, profile reed or double reed | |

| Drop Wire | Width of drop wire | 7-11mm |

| Length of drop wire | 125-180mm | |

| Thickness of drop wire | 0.2-0.65mm | |

| One channel for drop wire storage | Yes | |

| The Control Module | System | Windws operating system |

| Display | Touch screen | |

| Language | Chinese/English | |

| Power consumption | 3KW | |

| Electrical protection | Overload, short circuit protection | |

| Voltage | 380W | |

| Air Supply | Input air pressure | 7-10bar |

| Deviation in air pressure | <±0.5bar | |

| Minimum air supply | Total air supply 1350 Nl/min | |

| Pressure dew point | ﹣17℃ | |

| Oil content | Basic no oil content | |

| Impurity particles | Particle size <5um | |

| Indoor Conditions | Dust | Without abrasive dust and similar materials like glass |

| Humidity | 30-95% relative humidity, no condensation | |

| Temperature | Less than 15 ℃ temperature deviation in 10 hours | |

| Space Requirements | Ground material | Cast concrete |

| Flatness | Nonparallelism ±15, or total difference 30 mm | |

| Height | 260mm | |

| Layout space: if equipped with one creel machine/if equipped with two creel machine | 70㎡/100㎡ |

Color:Blue

Feature:Warp Penetration Effect

Shipping Port:Ningbo or Shanghai

Shipping Method:Shipping Shipping solutions for the selected quantity are currently unavailable

Payment Method:Secure payments

Every payment you make on Alibaba.com is secured with strict SSL encryption and PCI DSS data protection protocols-Textile Waving Machine

Product Details