What is the purpose of textile healds?

2024-08-01

The main purpose of textile healds is to help the loom form a shed during the weaving process so that the weft yarn can be interspersed and interwoven with the warp yarn to form the required fabric structure.

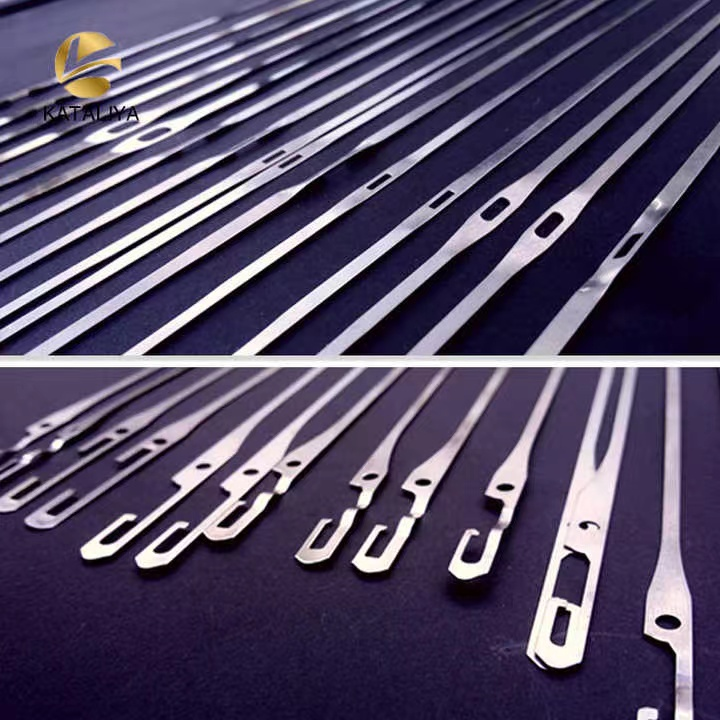

Textile healds, especially steel healds, have a promising application prospect in the textile industry. With the development of looms and the improvement of weaving requirements, imported stainless steel sheet healds have entered the domestic market one after another, such as sheet healds produced in Switzerland, the Czech Republic, Germany, Belgium, Japan, and Taiwan, China. Although the price is high and the supply is insufficient, domestic stainless steel sheet healds are also meeting market demand. Steel healds can be divided into steel wire healds and steel sheet healds according to their structure. The manufacturing process of steel wire healds includes twisted eye steel wire healds and welded ring eye steel wire healds.

In the construction of the loom, the heald frame is an important part of the loom opening mechanism. The lifting and lowering movement of the heald frame causes the warp yarn to move up and down to form a shed, so that the weft yarn can be introduced into the shed and interwoven with the warp yarn into a fabric. In addition, the role of the reed is also crucial. It not only determines the distribution density of the warp yarn and the width of the fabric, but also forms a shuttle flight channel with the shuttle board on the shuttle loom, or uses a special-shaped reed on the air-jet loom to reduce air flow diffusion and the role of the weft yarn channel.

In summary, the textile heald plays an indispensable role in textile production through its specific structure and function, ensuring the quality and production efficiency of the fabric.