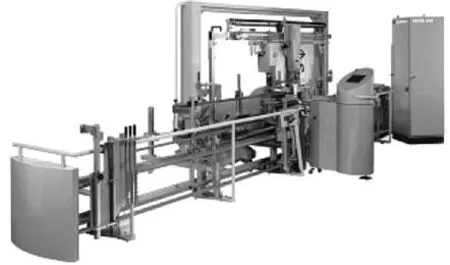

Four major modules of automatic warp drawing machine

2024-06-19

Heald Module

The healds are arranged in two groups on two heald magazine rails. The heald separator separates the healds one by one and each heald is conveyed to the rotating heald conveyor belt, which delivers the healds to the drawing-in position. Before drawing-in, the healds are aligned by centering the heald eye. After drawing in the warp yarns, the healds are conveyed to the desired heald frame position or heald bar. Then, the heald arranger pushes the healds to the heald frame or heald track according to the drawing-in cycle.

Yarn Module

From the warp layer to the heald frame yarn separator, the warp yarn is separated and delivered to the drawing-in hook. The drawing-in hook passes through the yarn holes of the steel box, heald and drop wire, and then pulls the yarn back to its original position. After the warp yarn is passed through the drop wire, heald and reed, it is discharged from the drawing-in hook and sucked by the suction nozzle. The warp sensor checks whether the yarn has been correctly drawn in.

Drop Wire Module

Preparation of the drop wire module is done in the drop wire warehouse. The drop wire separator separates the drop wires, and then a drop wire rotating head grabs the drop wires and brings them to the drawing-in position. After drawing in the warp yarns, the drop wires are collected by the drop wire distributor, ejected and arranged on the desired drop bar.

Reed Module

The reed is installed on the reed transport vehicle. During the warp drawing, the optical monitoring and control system of the reed checks the transport of the reed according to the fineness of the reed and the expected drawing. 1 piece enters the reed teeth, and the warp drawing hook draws the warp yarn into the reed teeth. The opening of the reed teeth is large enough for the warp drawing hook and the yarn to pass smoothly.